Are you in need of effective communication when it comes to maintaining your construction equipment? Crafting a well-structured maintenance request letter can streamline the process and ensure that your equipment stays in top shape. In this article, we'll explore the essential elements of a compelling maintenance request, from addressing the right person to outlining specific needs. So, let's dive in and learn how to write a maintenance request that gets results!

Equipment Details

Construction equipment maintenance requests require detailed information to ensure efficient service. Each equipment entry begins with the Equipment Identification Number (EIN) crucial for tracking maintenance history. Include the type of equipment, such as excavator or bulldozer, along with the make and model (e.g., Caterpillar D6T) for specific service protocols. Record the operational hours or usage statistics, which are essential for scheduling preventive maintenance (typically every 250 hours for heavy machinery). A description of current issues, like hydraulic leaks or engine malfunctions, is vital for prioritizing repairs. Lastly, include the location of the equipment, such as site address or job number, to facilitate timely service response.

Maintenance Description

Regular maintenance of construction equipment is crucial for optimal performance and longevity, including excavators, bulldozers, and cranes. Scheduled inspections (typically every 250 operating hours) focus on checking hydraulic systems for leaks and ensuring fluid levels are adequate. Replacement of worn-out tracks or tires plays a significant role in maintaining traction and stability on job sites, which are often uneven and challenging. Lubrication of moving parts prevents wear and tear, enhancing efficiency and reducing the likelihood of mechanical failure. A detailed record of service history, including parts replaced and maintenance actions taken, is essential for tracking equipment health and facilitating future repairs. Furthermore, compliance with safety standards set by organizations like OSHA (Occupational Safety and Health Administration) is necessary to ensure worker safety and reduce liability for the construction company.

Urgency Level

Construction equipment maintenance requests, particularly those involving heavy machinery like excavators and bulldozers, often adhere to strict urgency levels. Scheduled maintenance (e.g., routine inspections every 250 operational hours for oil changes) ensures optimal performance and safety. Urgent requests may arise from equipment failures causing downtime, such as a hydraulic system malfunction or a blown tire set, impacting project timelines. Rapid response protocols often dictate prioritizing these requests, especially in high-stakes environments like construction sites in urban areas, where costly delays can exceed thousands of dollars per day. In these scenarios, clear communication channels (e.g., dedicated maintenance hotline) and prompt scheduling (within 24 hours) are crucial to mitigate risks associated with equipment failure.

Contact Information

Construction equipment maintenance ensures optimal performance and safety on job sites. Regular inspections of machinery such as excavators, bulldozers, and cranes prevent costly downtime. Scheduling maintenance services from authorized providers, like Caterpillar or Komatsu, typically involves providing essential contact information including company name, address (e.g., 123 Construction Ave, Cityville), phone number (e.g., 555-123-4567), and email address (e.g., info@constructioncompany.com). Detailed maintenance requests can include specific equipment models and related issues, enabling technicians to prepare adequately for on-site visits. Proper communication fosters efficient service delivery, enhancing the longevity and effectiveness of heavy construction machinery.

Authorization Signature

Construction equipment maintenance requests ensure optimal performance and longevity of machinery, such as backhoes or excavators. Timely maintenance checks can prevent costly repairs, improve safety on-site, and ensure compliance with industry regulations. Professionals usually recommend scheduling inspections every 100 operational hours. Additionally, maintenance records should be meticulously documented for equipment like bulldozers, as these records assist in determining warranty eligibility and resale value. A clear authorization signature from management or a designated representative is essential for processing maintenance requests, reflecting accountability and approval for necessary expenditures.

Letter Template For Construction Equipment Maintenance Request Samples

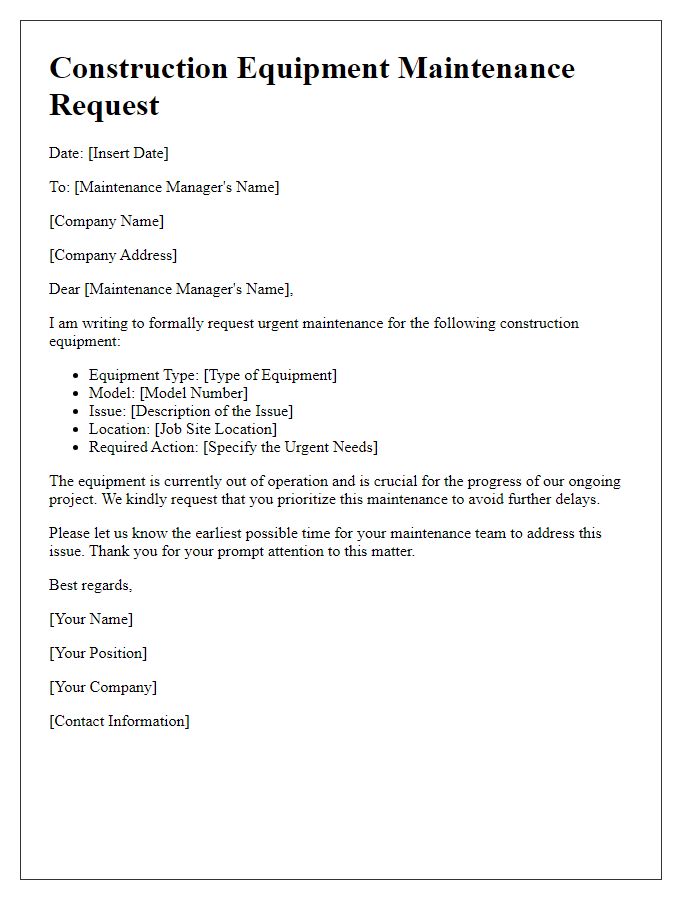

Letter template of construction equipment maintenance request for urgent repairs

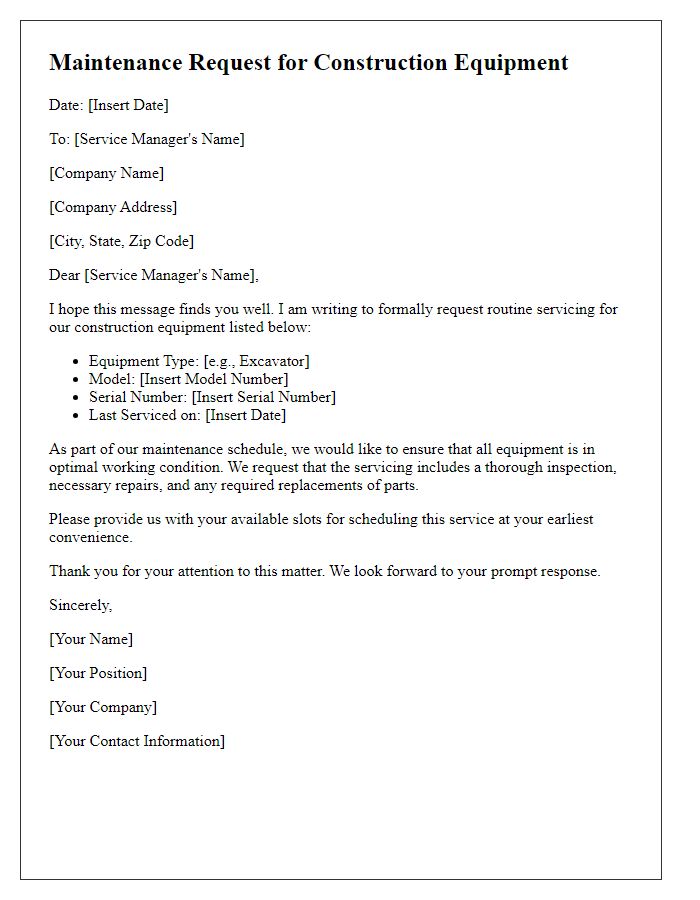

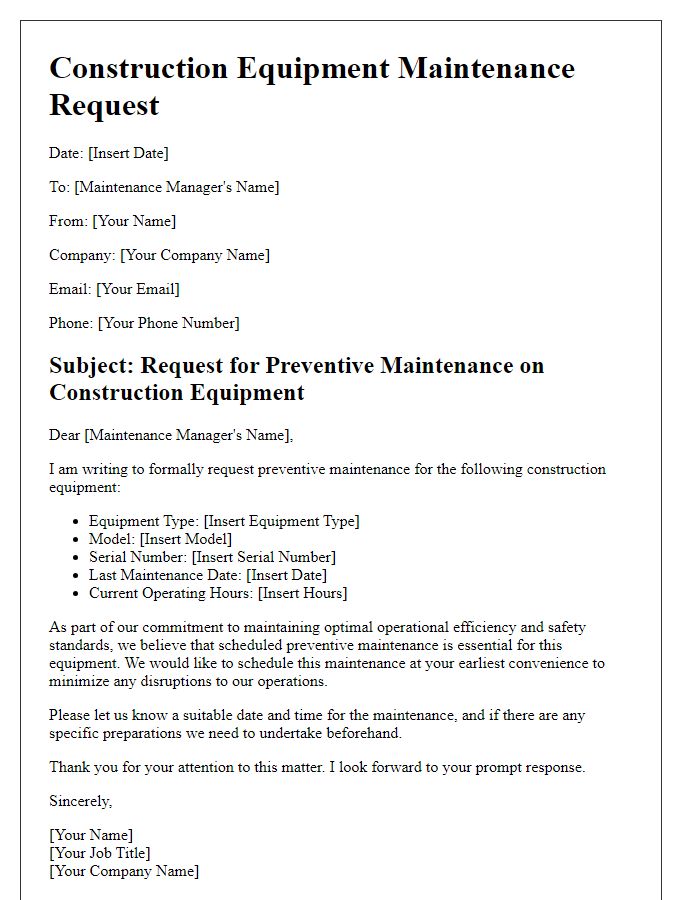

Letter template of construction equipment maintenance request for routine servicing

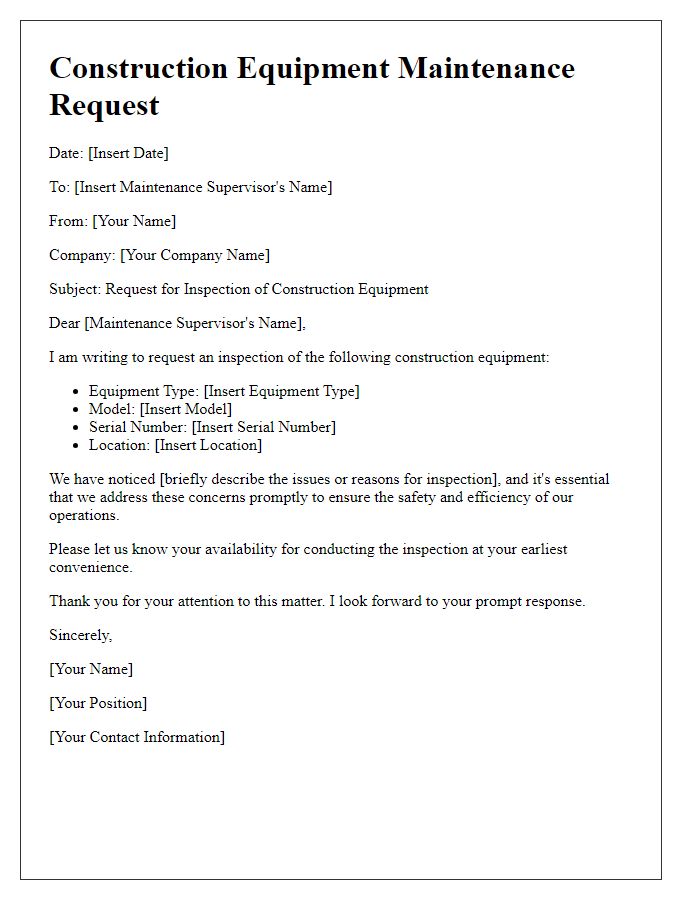

Letter template of construction equipment maintenance request for inspection

Letter template of construction equipment maintenance request for troubleshooting issues

Letter template of construction equipment maintenance request for oil change

Letter template of construction equipment maintenance request for safety checks

Letter template of construction equipment maintenance request for parts replacement

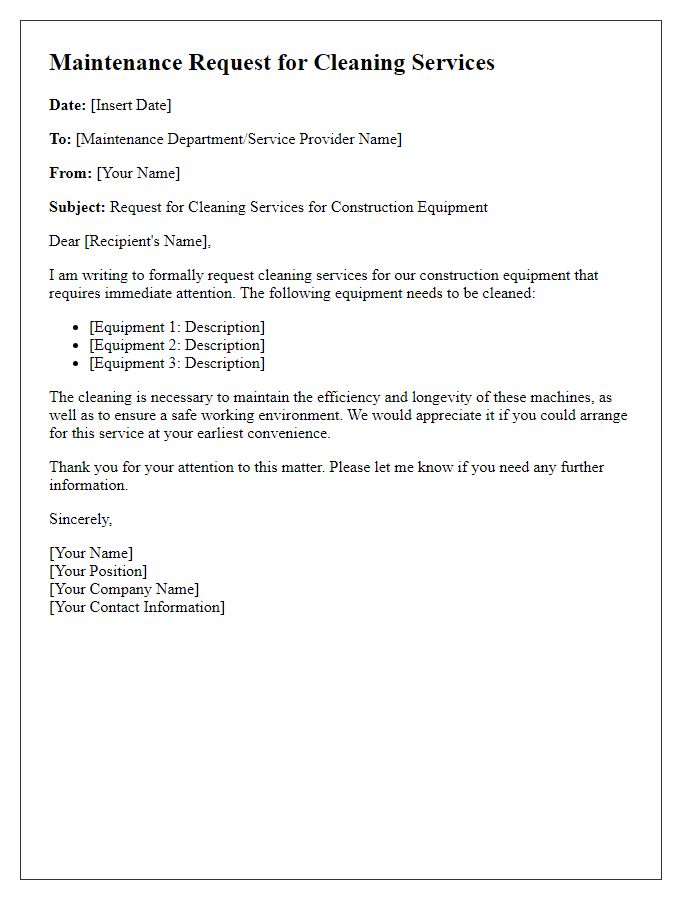

Letter template of construction equipment maintenance request for cleaning services

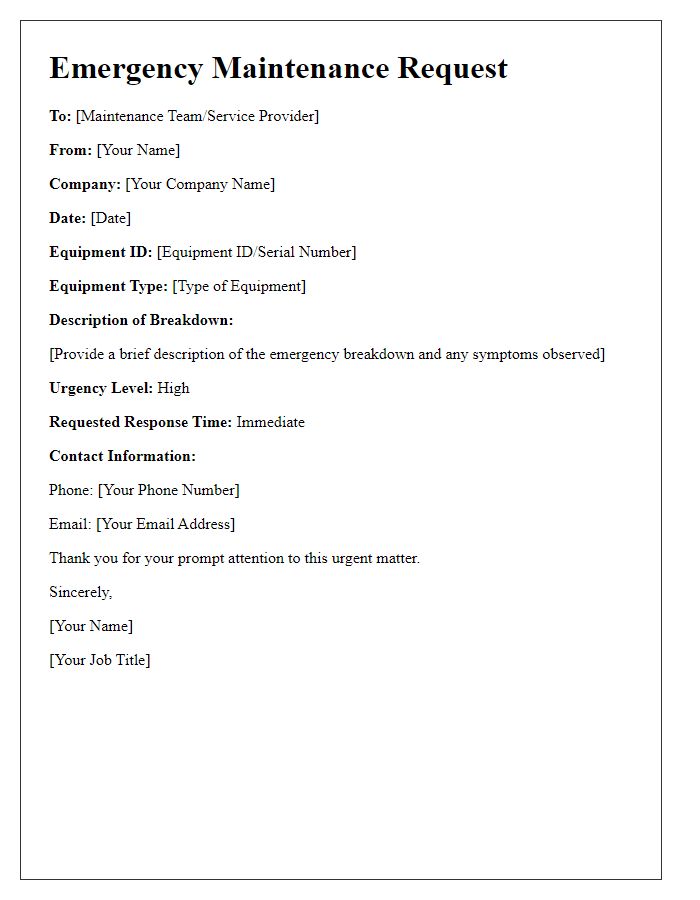

Letter template of construction equipment maintenance request for emergency breakdown

Comments