Are you tired of overspending on supplies and services? Implementing a cost-saving solution with the right vendor can significantly boost your bottom line. In this article, we'll explore effective strategies to negotiate better deals and streamline your purchasing processes. Join us as we delve into smart tips that can transform your approach to vendor management and ultimately save your business money.

Concise and Clear Objective

A vendor cost-saving solution proposal aims to reduce expenses while maintaining quality and efficiency. This proposal often highlights potential cost reductions of 10-20% based on data-driven assessments. Key components include a detailed analysis of current vendor contracts, identification of alternative suppliers, and examples of successful case studies in similar industries, such as retail and manufacturing. Implementing strategic sourcing techniques can streamline procurement processes, reduce waste, and enhance supply chain management. Expected outcomes encompass improved financial metrics, fostering long-term relationships with vendors, and achieving sustainable savings that bolster overall profitability.

Demonstration of Value Proposition

Effective vendor cost-saving solutions can significantly enhance operational efficiency and maximize profit margins for companies. A comprehensive value proposition should present quantifiable savings, such as a reduction in supply chain expenses by up to 20%, alongside insights from successful case studies within the industry. Highlight the robustness of innovative technologies, like cloud-based analytics platforms, which streamline inventory management and reduce waste. Emphasize unique aspects of the partnership, including dedicated support teams and customized service plans tailored to specific business needs, fostering collaboration between vendor and client. The ultimate goal is to create a compelling narrative focused on measurable outcomes, enabling clients to visualize potential impacts in both short-term gains and long-term sustainability.

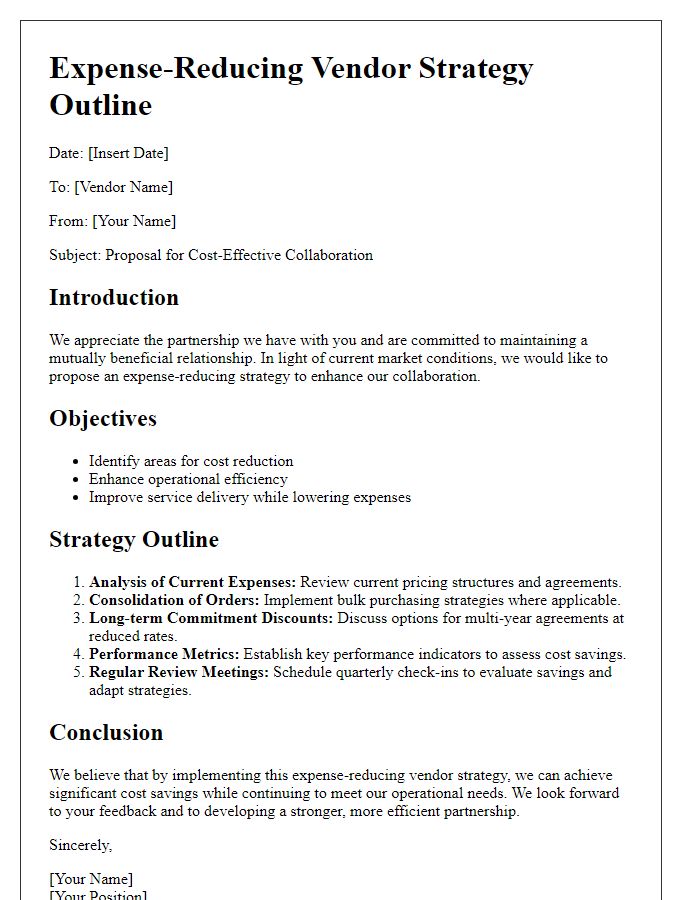

Detailed Cost-Benefit Analysis

A detailed cost-benefit analysis offers essential insights to assess vendor cost-saving solutions effectively. This analysis includes a comprehensive evaluation of projected savings, which may encompass direct savings from bulk purchasing options or negotiated discounts. It factors in implementation costs such as training staff at a specific facility, which can yield initial expenses but ultimately leads to long-term efficiencies. Additionally, the analysis includes timelines, projecting a 10% reduction in operational costs within the first year after adopting these solutions. It also examines potential revenue impacts, helping companies make informed decisions that align with strategic financial goals. Adjusting for market changes and supplier reliability is crucial, ensuring sustainable savings that can be observed in similar industries, such as retail or manufacturing, where vendor negotiations play a significant role in overall profitability.

Tailored Solutions and Customization

Tailored solutions and customization can significantly enhance operational efficiency, particularly in manufacturing industries. Vendors like Siemens and GE have reported a 20% reduction in costs through bespoke software solutions specifically designed for their production lines. Customization allows for the integration of advanced analytics to forecast demand accurately, leading to minimized excess inventory and waste. Additionally, by utilizing tailored supply chain systems, companies can improve logistics efficiency, resulting in faster turnaround times and reduced transportation costs. Engaging stakeholders in the customization process fosters collaboration and ensures that the solutions directly address the unique challenges faced by businesses, ultimately driving increased profitability and sustainability.

Strong Call to Action and Follow-up Plan

A comprehensive vendor cost-saving solution proposal highlights innovative strategies aimed at reducing expenses while maintaining product quality. For example, bulk purchasing agreements can lead to significant savings, possibly up to 20% or more on essential materials. Implementing value engineering methods can enhance product design efficiency, further lowering manufacturing costs without sacrificing functionality. Additionally, leveraging technology for supply chain optimization can streamline operations, ensuring timely deliveries while minimizing excess inventory. A structured follow-up plan should include scheduled meetings to assess progress regularly, typically quarterly, and to explore additional savings opportunities, enhancing long-term partnerships. Establishing key performance indicators (KPIs) such as cost reduction percentages and delivery time improvements will provide measurable outcomes to track success and areas for future focus.

Comments