Are you tired of dealing with faulty equipment that disrupts your daily routine? It can be incredibly frustrating when the tools you rely on fail to perform as expected, affecting both your productivity and peace of mind. Thankfully, there are steps you can take to address these issues, including writing a formal letter for equipment replacement. Join me as we explore how to craft an effective letter that not only communicates your concerns but also paves the way for a swift resolutionâread on to learn more!

Contact Information

Faulty machinery in manufacturing processes can severely disrupt productivity and increase operational costs. For instance, a defective conveyor belt system at a plant in Texas can lead to significant delays in material transport, resulting in a backlog of production by up to several days. Immediate replacement of such essential equipment, like hydraulic pumps or electric motors, is crucial to restore normalcy. Timely communication to suppliers, including detailed descriptions of the fault and model numbers, helps expedite the replacement process. Documentation of previous maintenance records can support claims for warranty service, ensuring minimal downtime. Prompt action in addressing equipment failures not only sustains workflow but also preserves overall efficiency in industrial settings.

Subject Line

Subject Line: Request for Replacement of Faulty Equipment

Description of Issue

Precision machinery often requires regular maintenance and replacement of faulty components. A common issue arises with the hydraulic pump model (XYZ-123) utilized in industrial settings, where years of heavy use (over 10,000 operational hours) can lead to significant wear. Users report symptoms such as irregular pressure levels (dropping below 150 PSI), which can compromise operational safety and efficiency on factory lines. The deterioration of seals and O-rings, often made of rubber compounds (such as Nitrile or Viton), contributes to fluid leaks and loss of power. In some instances, it has led to the complete shutdown of operations in facilities like those in Detroit, Michigan, highlighting the critical need for timely replacement and servicing of these essential tools to maintain production flow.

Request for Action

In an industrial setting, malfunctioning machinery can significantly impact operational efficiency. For instance, a broken conveyor system in a warehouse environment, such as the one in Seattle, can disrupt logistics and lead to delayed shipments. Common issues include motor failures, which occur in about 15% of units, or misalignment that can cause up to a 20% decrease in productivity. Prompt action is crucial; replacement components can be sourced from manufacturers within two weeks, and plans to retrofit equipment may begin immediately after replacement authorization. Addressing these issues effectively ensures minimal downtime and sustained productivity in the overall operation.

Polite Closing

A faulty equipment replacement request often requires careful detailing of the issue, the specific model, and desired resolution. Consider including key information such as ticket numbers, purchase dates, and warranty status. When addressing customer service, express gratitude for their assistance, and mention any previous positive experiences with the brand to reinforce a relationship. A polite closing may include phrases such as "Thank you for your attention to this matter" or "I appreciate your prompt response." Aim for a courteous tone, ensuring your contact information is clearly stated for follow-up.

Letter Template For Faulty Equipment Replacement Samples

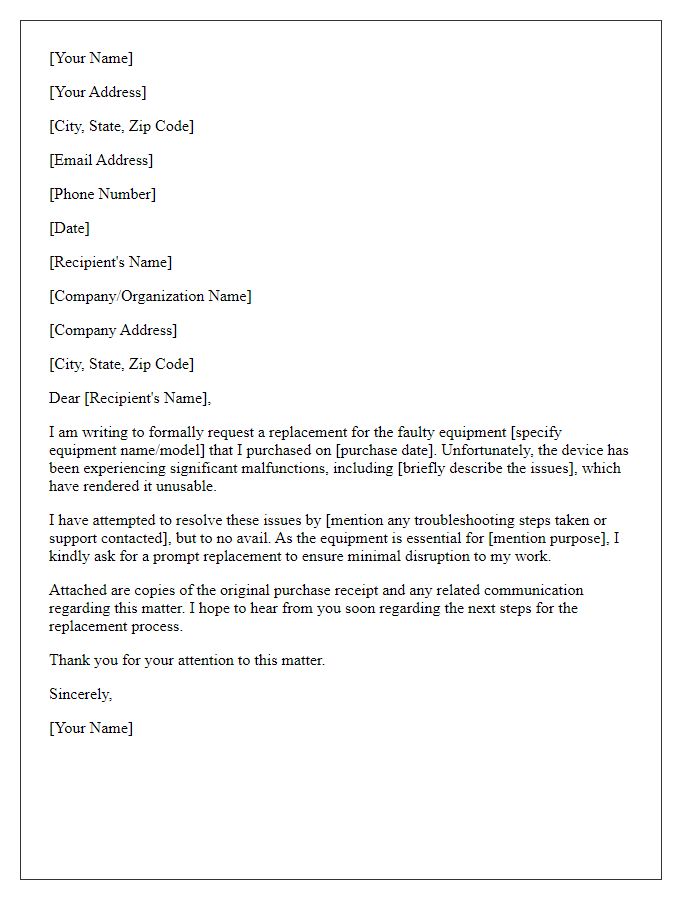

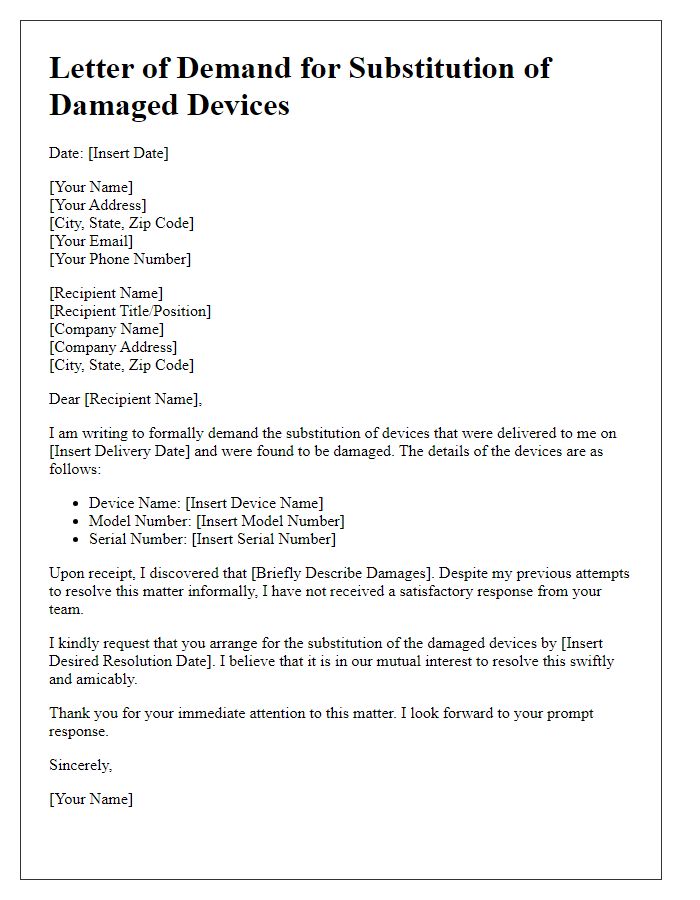

Letter template of request for faulty equipment replacement due to malfunction

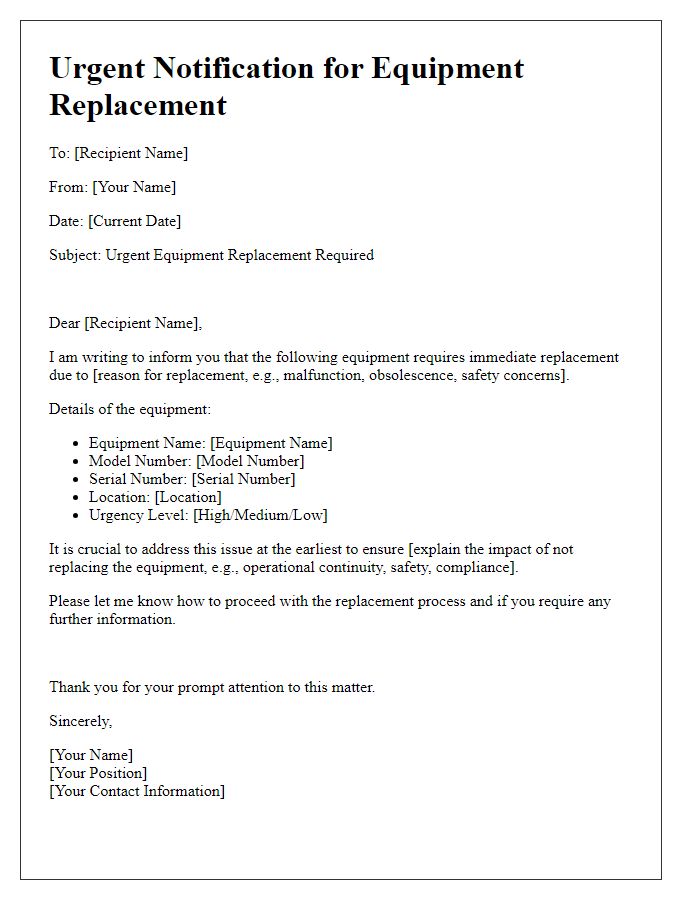

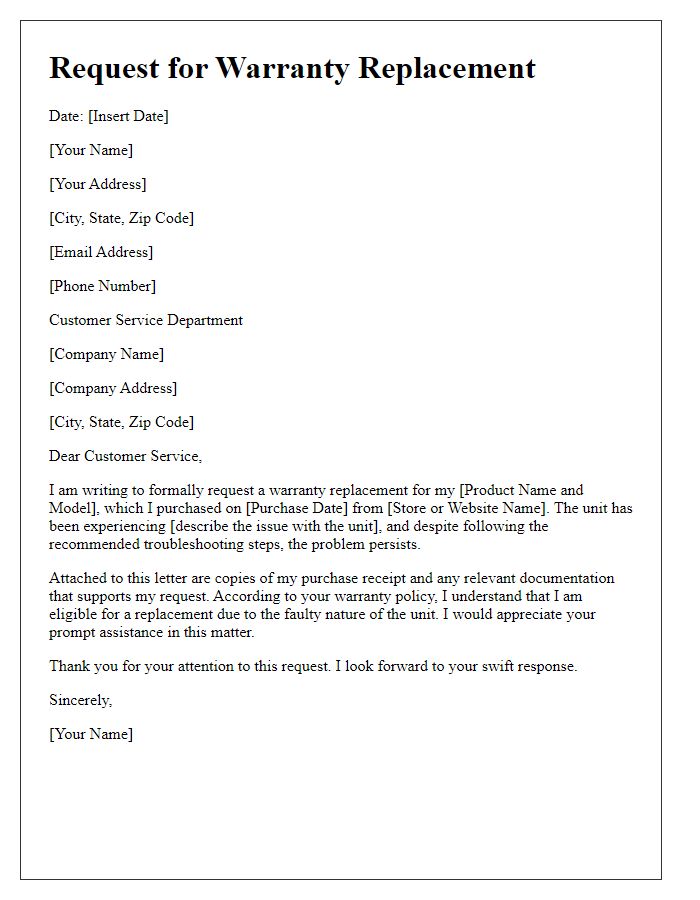

Letter template of notification for urgent equipment replacement required

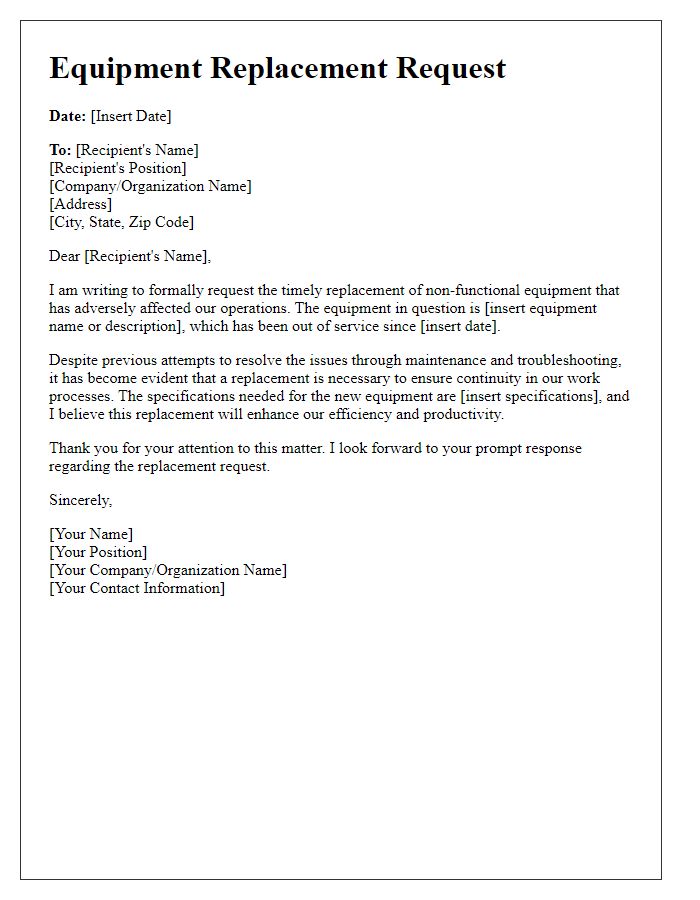

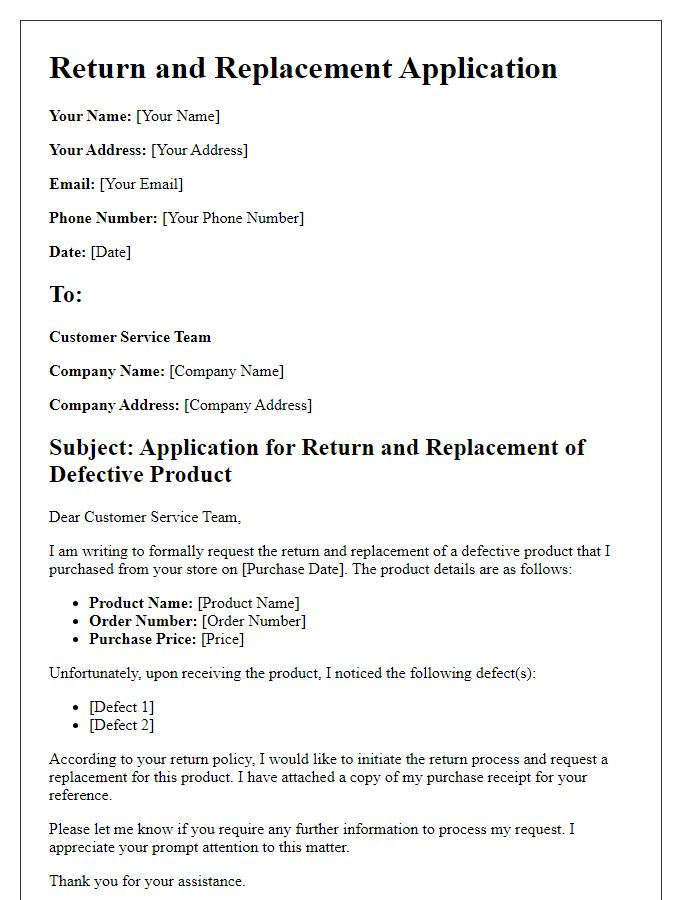

Letter template of communication for timely replacement of non-functional equipment

Comments