Welcome to our guide on conducting an effective supplier performance evaluation! In today's competitive market, understanding how your suppliers contribute to your success is crucial for making informed decisions. This process not only helps you identify strengths and areas for improvement but also fosters stronger partnerships with your suppliers. Ready to learn how to streamline your evaluations and enhance your supplier relationships? Read more to discover our comprehensive letter template!

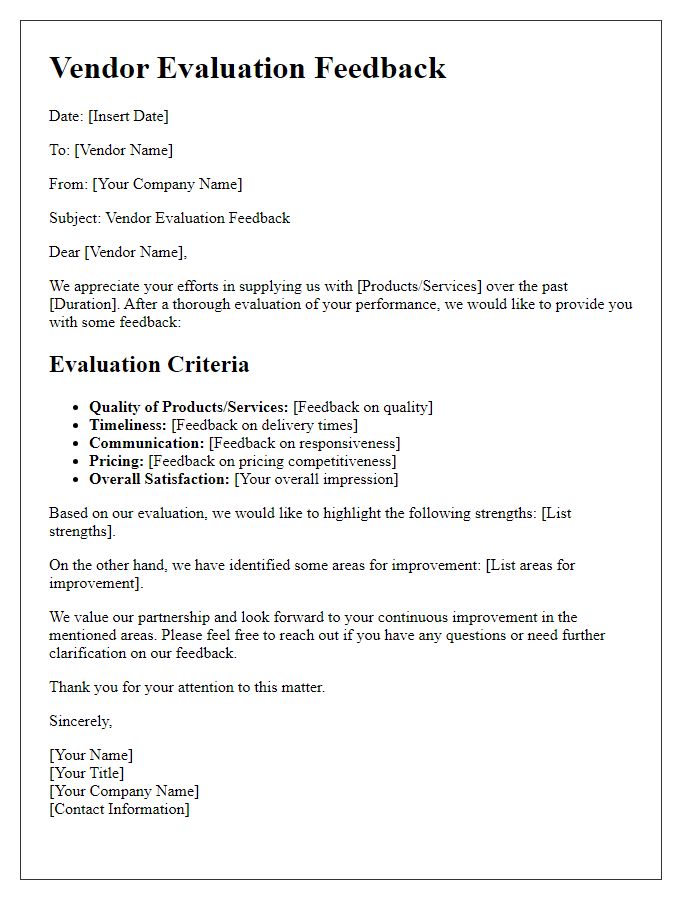

Evaluation Criteria

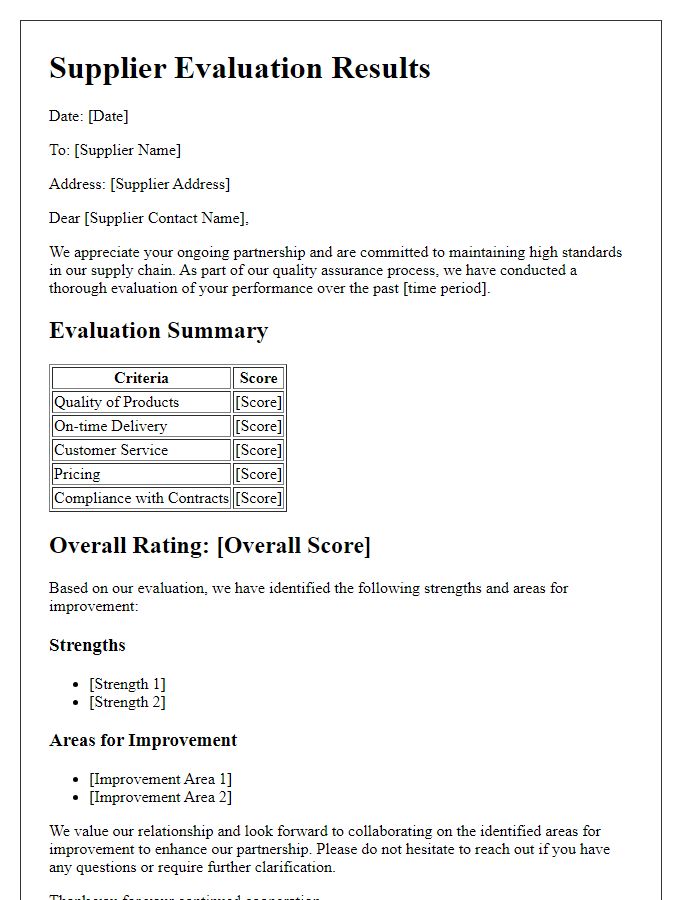

Supplier performance evaluation involves assessing various criteria to ensure optimal relationships and product delivery. Key aspects include quality of goods (measured by defect rates below 2% for manufactured components), on-time delivery (ideally 95% of shipments arriving within the agreed timeline), responsiveness to inquiries (response times within 24 hours for standard queries), and overall communication (effectiveness rated through surveys with a minimum score of 4 out of 5). Financial stability (evaluating credit scores and risk assessments) also plays a vital role, as does innovation (measured by the implementation of at least one new product or process improvement per year). Sustainability practices (compliance with ISO 14001 environmental standards) increasingly factor into evaluations, emphasizing commitment to responsible sourcing and environmental management. Additionally, customer service quality, gauged by customer satisfaction scores, is essential for maintaining collaborative relationships in a competitive market.

Performance Metrics

Supplier performance evaluation relies on a comprehensive analysis of key metrics to determine the effectiveness and reliability of vendor partnerships. Metrics such as on-time delivery percentage, typically aimed at achieving over 95%, play a crucial role in assessing punctuality. Quality assurance scores, derived from inspection results identifying defects per million units, are pivotal, with a benchmark of less than 1,000 defects preferred. Cost efficiency, measured by total spending versus budget projections, influences overall profitability, while responsiveness, evaluated by average response time to inquiries, ideally under 24 hours, reflects the supplier's customer service agility. Moreover, compliance with contracts, indicated by adherence to agreed terms and conditions, ensures that legal obligations are met, fostering trust and stability in business relationships.

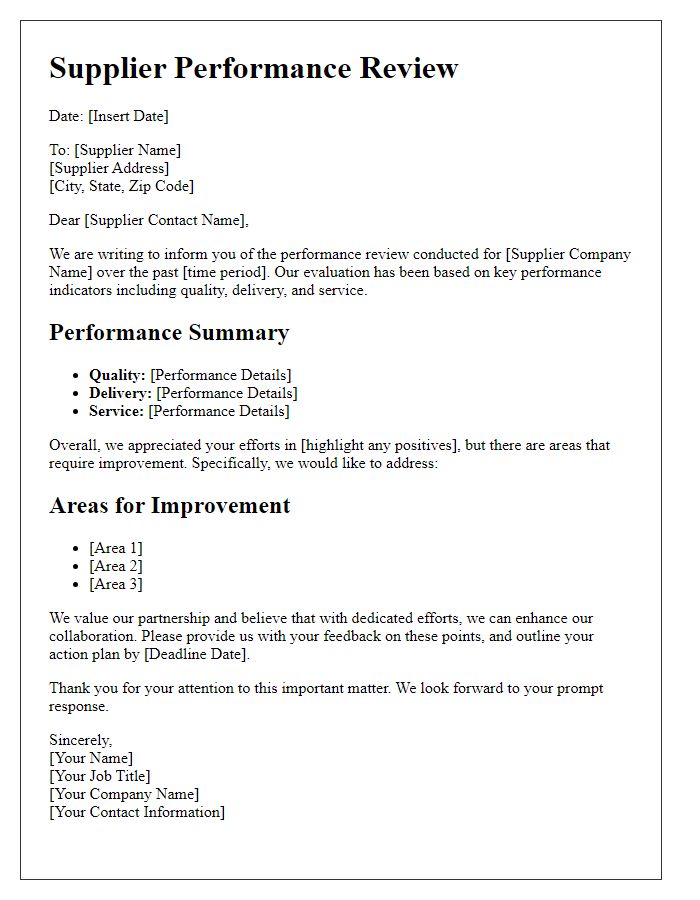

Feedback and Comments

Supplier performance evaluation emphasizes key aspects such as delivery timeliness, product quality, and communication effectiveness. For instance, timely deliveries within agreed lead times (typically 30 days for standard orders) are crucial for maintaining operation schedules in manufacturing environments. High-quality products, characterized by minimal defect rates (below 2% is often considered acceptable), ensure customer satisfaction and reduce return rates. Moreover, effective communication, assessed through response times (ideally under 24 hours for inquiries), influences relationship strength and problem resolution efficiency. Feedback should encapsulate both positive elements, such as proactive issue resolution, and areas needing improvement, including delays or inconsistencies in product specifications, to provide a comprehensive assessment of supplier performance.

Improvement Opportunities

Supplier performance evaluation reveals critical areas for enhancement. On-time delivery rates fell to 78% in Q3 2023, significantly below the desired benchmark of 95%, impacting production schedules at our primary facility in Grand Rapids, Michigan. Quality assurance metrics indicate an increase in defect rates, rising to 4.5% compared to the acceptable threshold of 1.5%. Communication lapses have also been noted, with response times exceeding 48 hours for urgent inquiries, affecting project timelines. Implementing a robust tracking system for shipments could enhance delivery efficiency. Regular feedback sessions and a structured quality review process may address product consistency issues, fostering a more collaborative relationship. Engaging in continuous improvement workshops could align our objectives and expectations, enhancing overall performance and satisfaction.

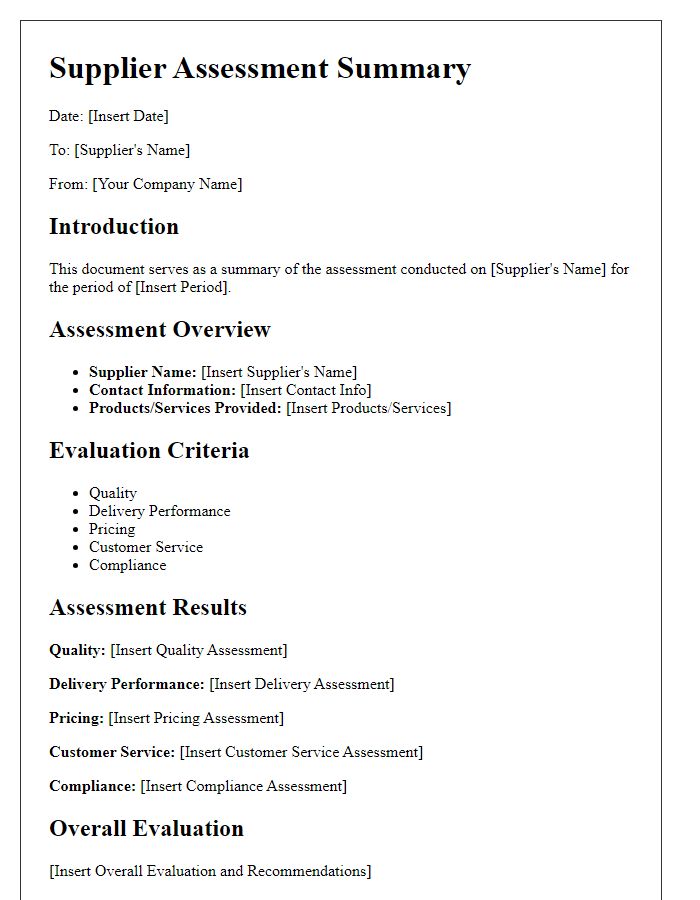

Future Collaboration Plans

Supplier performance evaluations help assess collaboration potential, such as sharing expectations and performance metrics. Establishing clear communication channels fosters transparency and strengthens relationships. Future collaboration plans may include joint initiatives aimed at improving supply chain efficiency. Innovative technologies, such as data analytics, can enhance real-time tracking of inventory levels, ensuring timely deliveries. Regular performance reviews, ideally on a quarterly basis, should review production quality and delivery times, promoting trust and accountability. Training sessions for supplier teams can bridge knowledge gaps, aligning priorities and processes. Collaborative workshops may focus on sustainability initiatives, enhancing corporate social responsibility practices across both organizations.

Comments