When collaborating with suppliers, confirming the receipt of goods is an essential step in maintaining a smooth operation. This process ensures that both parties are on the same page regarding the quantity and quality of items received. Not only does it foster trust, but it also allows for efficient handling of any discrepancies that may arise. Curious about how to craft the perfect goods receipt confirmation letter? Read on for a handy template that can streamline your communication!

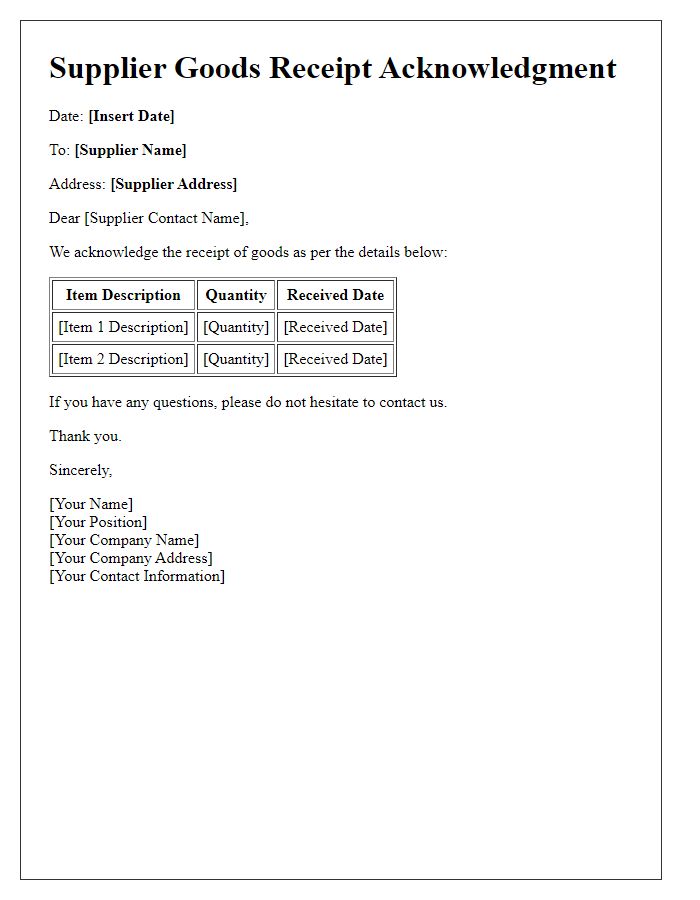

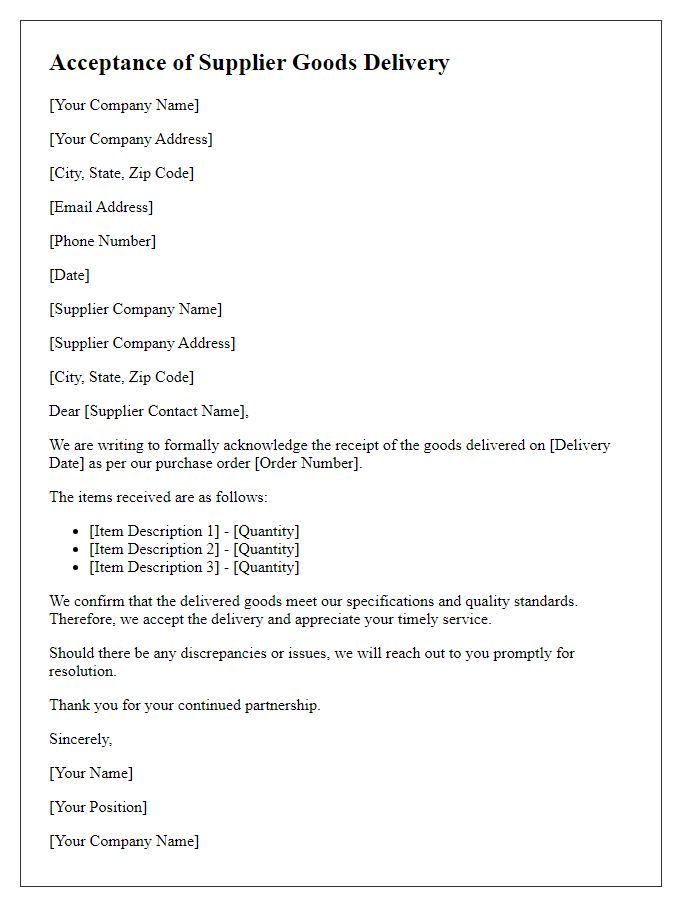

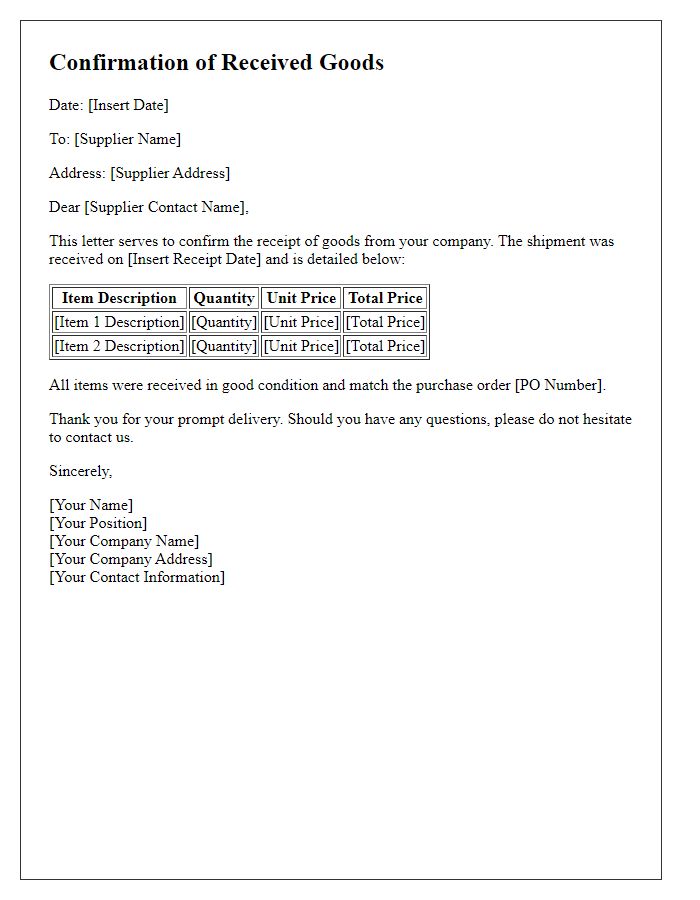

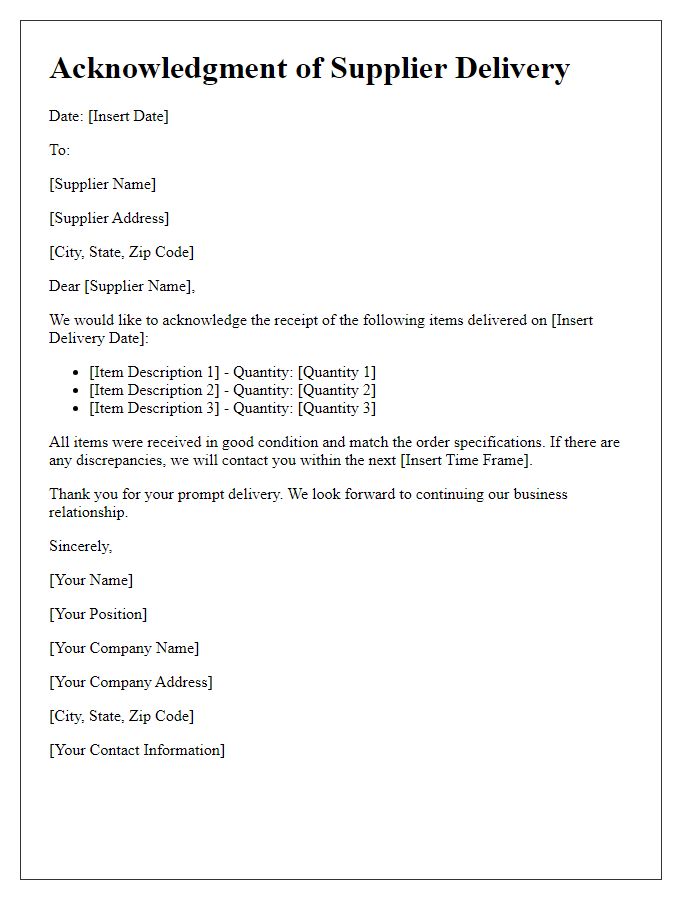

Supplier and recipient contact details

The receipt confirmation process involves the prompt acknowledgment of goods received from suppliers, often critical in warehouse management and supply chain logistics. Accurate delivery documentation ensures that all items are accounted for and discrepancies are quickly identified. Important elements include supplier contact details, such as company name and address, often located in regions like California or New York. Recipient contact information should also be clearly specified, including the warehouse location, typically situated in urban centers for easier distribution. Each item on the delivery note must be identified by SKU numbers and descriptions, ensuring that merchandise meets the quality standards expected. Timely confirmation of receipt can prevent supply chain disruptions and improve supplier relationships, fostering a reliable business environment.

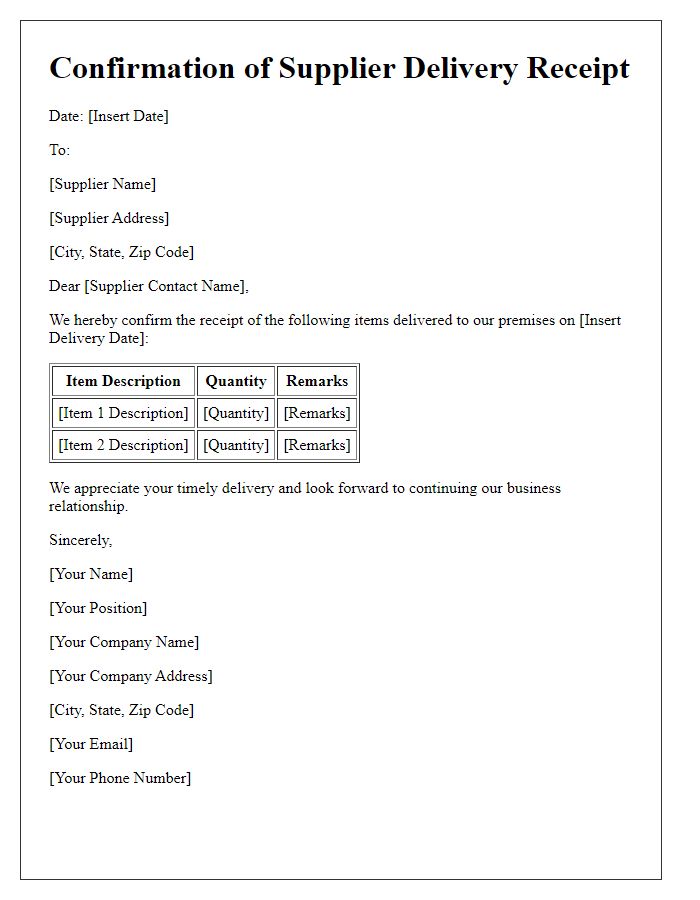

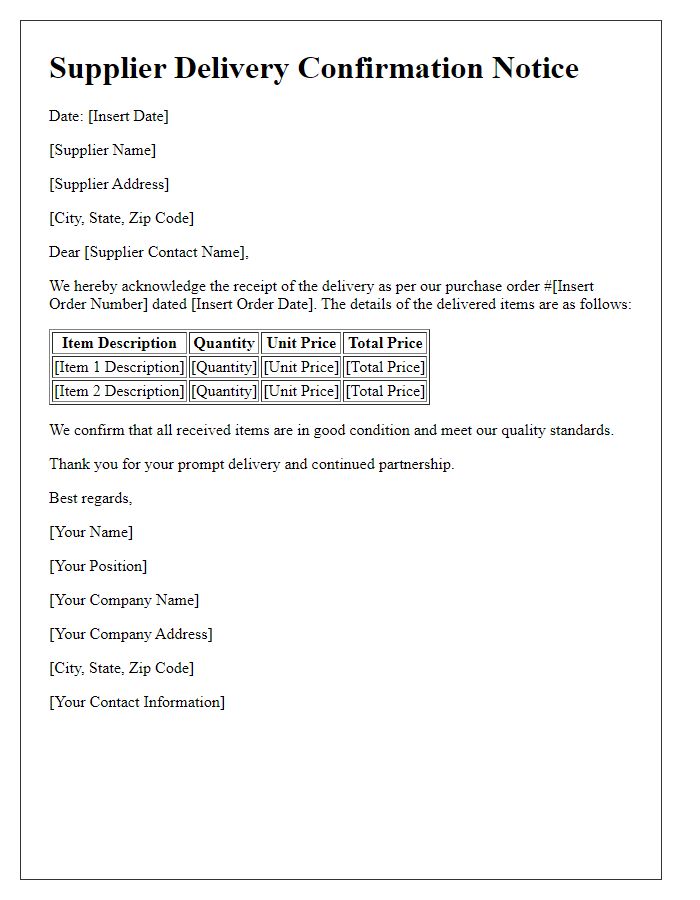

Purchase order number and date

The goods receipt confirmation process for suppliers involves acknowledging the receipt of ordered items, which includes essential details such as the purchase order number and date. This confirmation helps streamline inventory management and ensures accuracy in supply chain operations. The purchase order number, a unique identifier often consisting of digits and letters, links the received goods to specific orders, promoting accountability. Recording the date of receipt, which could signify logistical timelines or payment schedules, is crucial for maintaining accurate records. Proper documentation of these elements aids in quality control, allowing for efficient resolution of discrepancies between the order and the delivered products.

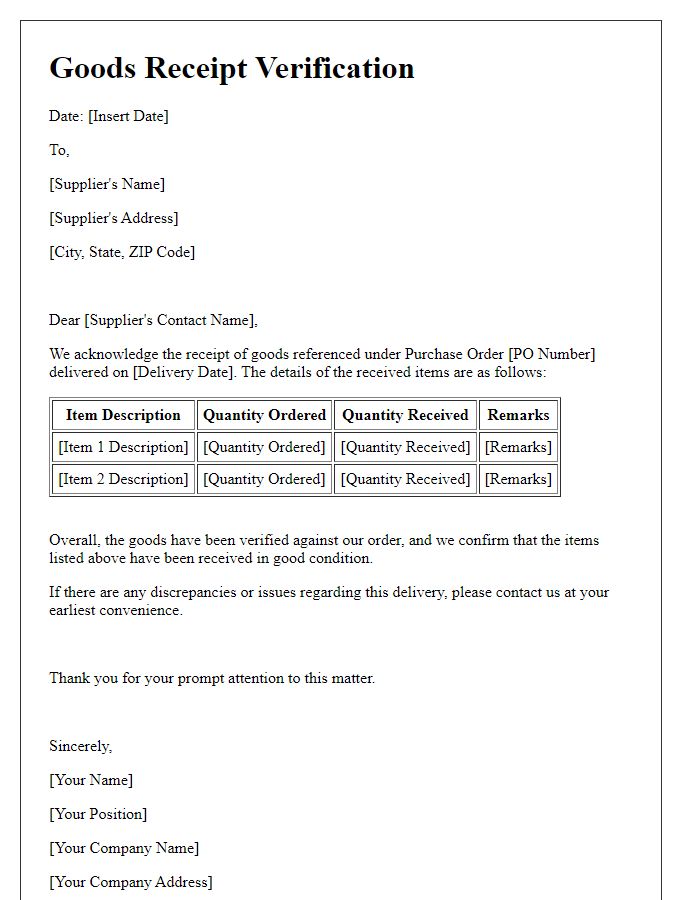

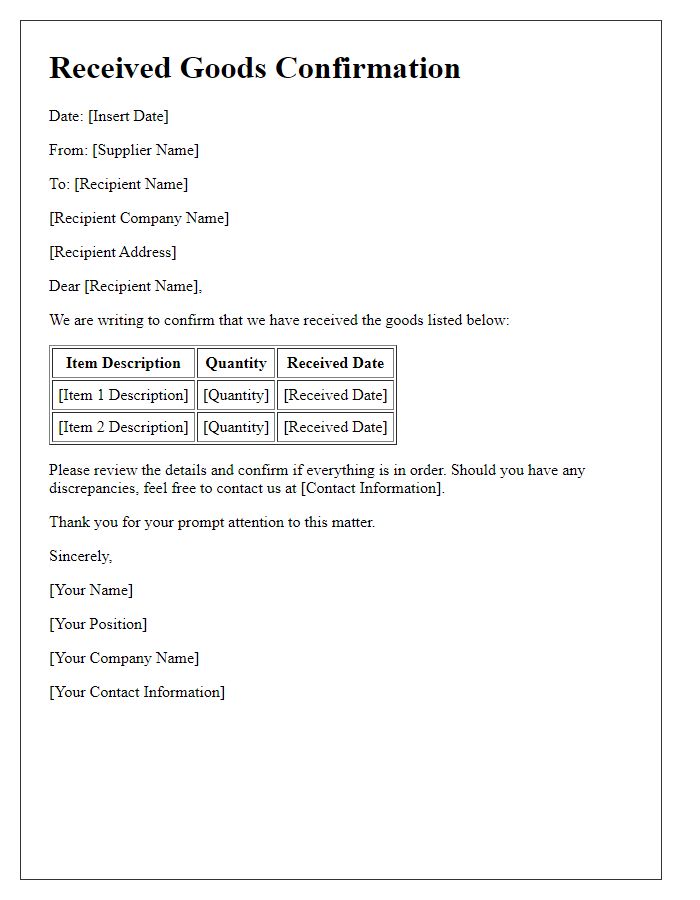

Description and quantity of goods received

Upon receiving the delivery of goods from the supplier, the warehouse team conducted a thorough inspection of the shipment, which included over 150 units of high-quality office chairs and 300 packages of premium printer paper. Each chair, manufactured by Ergohuman in 2022, was examined for defects, while the printer paper, sourced from Uline, was checked for quality and count. The detailed inventory confirmed that all goods matched the purchase order specifications, with no discrepancies noted in both quantity and condition. This successful receipt of goods is documented to ensure accurate stock management and efficient inventory tracking within our logistics system.

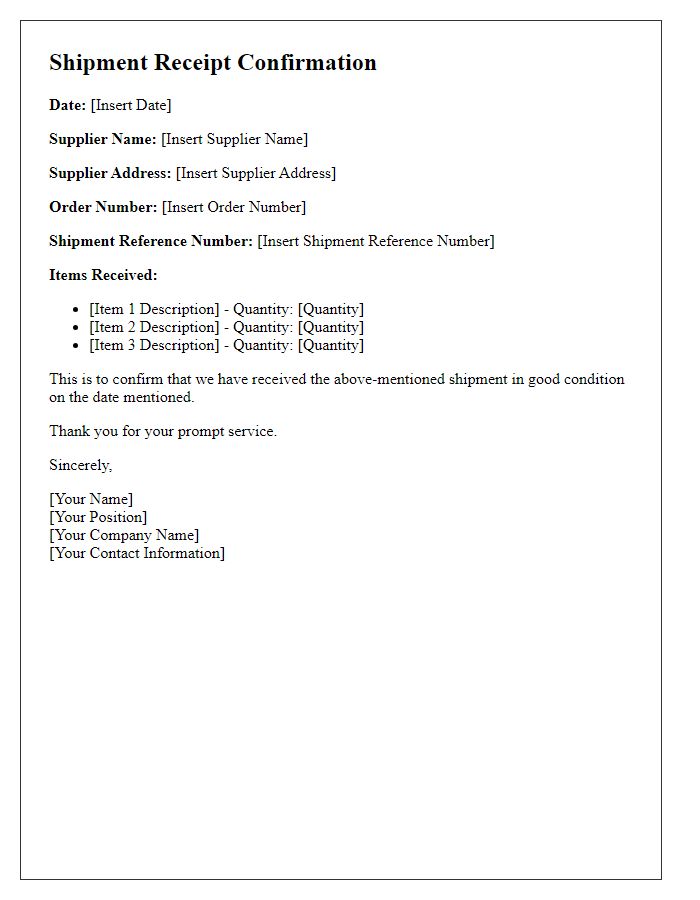

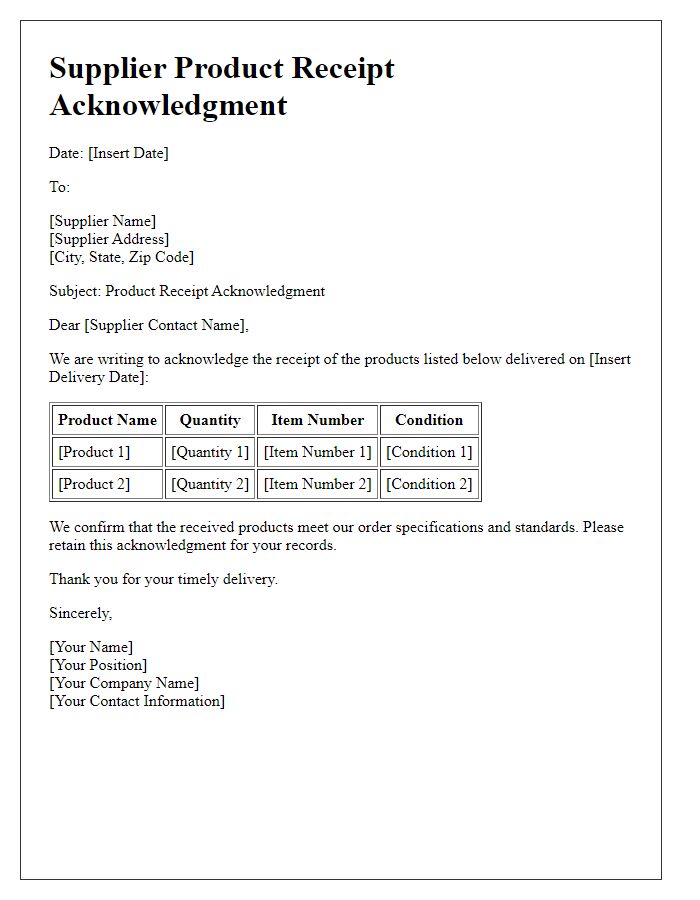

Condition and inspection status of items

Upon inspection of the delivered goods, several key items were evaluated for condition and compliance with our purchase order specifications. The shipment, consisting of 100 units of Model X (part number 12345), arrived in good condition without visible damages. Each unit underwent a thorough functional test, confirming operational status and quality standards. Packaging integrity was also assessed to ensure protection during transit, with all boxes intact and sealed. Specific attention was given to expiration dates on perishable items, notably food products, which were verified as within acceptable limits. Additional paperwork, including certificates of conformity and delivery receipts, were reviewed and matched our records, ensuring full compliance with regulatory requirements. Overall, the inspection confirms that the received goods meet our standards and are ready for further processing.

Acknowledgment and confirmation statement

Goods receipt confirmation serves as a vital process in supply chain management. Upon arrival of ordered goods, a company (such as ABC Corporation located in New York) verifies the shipment against the purchase order (PO number 12345) to ensure accuracy. This involves checking item quantities (e.g., 50 boxes of product XYZ) and inspecting the condition of items for any damage. Once verification is complete, an acknowledgment is sent to the supplier (Supplier LLC based in California) confirming receipt of the goods. This confirmation typically includes details like the delivery date (October 15, 2023), a list of received items, and any discrepancies noted (such as missing items or damaged packaging). Proper documentation of this process supports inventory management and maintains communication integrity between supplier and recipient.

Comments