Are you tired of dealing with supplier errors that disrupt your workflow? If so, you're not aloneâmany businesses face this challenge and need a clear process to address it. Establishing an effective error reporting procedure can save you time, money, and headaches down the line. Join us as we explore the essential steps to create a robust system that enhances communication and minimizes disruptionâread more to find out how!

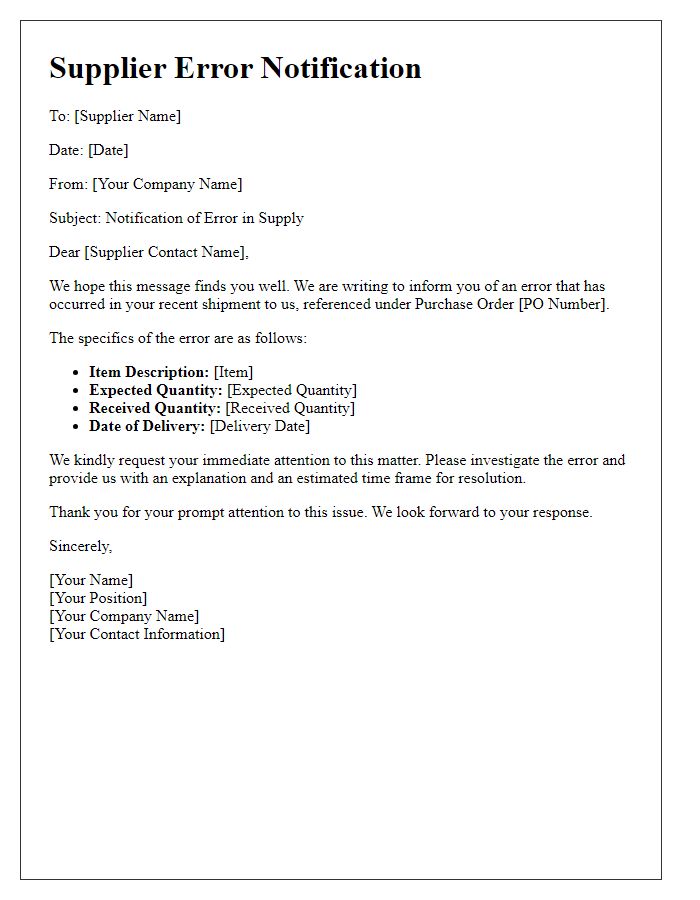

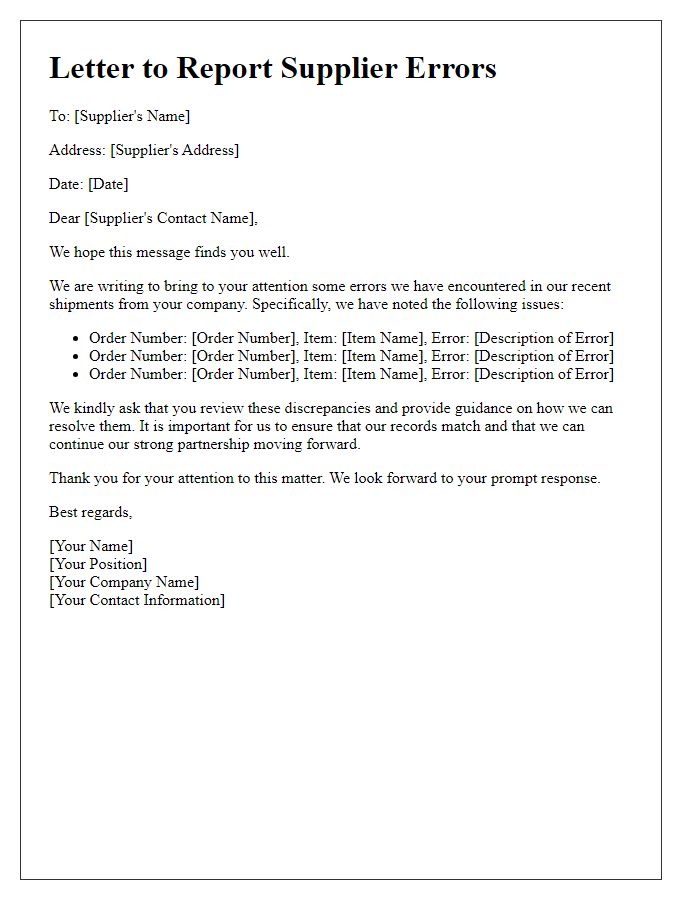

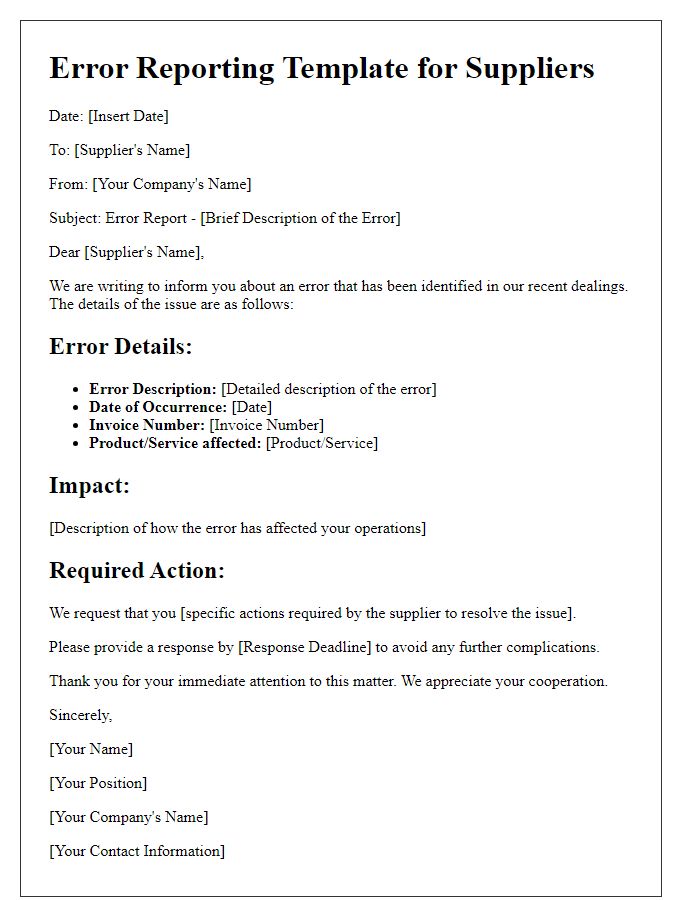

Clear Explanation of the Error

Clear communication regarding supplier errors is essential in maintaining efficient product supply chains. For instance, incorrect shipments can lead to inventory shortages at retail locations like Walmart or Target. Reporting an error includes detailing the specific product involved, such as a quantity discrepancy affecting 500 units of a specific SKU. It is crucial to document the order number, shipment date, and specific errors, such as incorrect item sizes or missing components. Providing photographic evidence, like images of incorrect labels or missing items, bolsters the report's credibility. Moreover, outlining potential impacts, such as financial losses or customer dissatisfaction, highlights the urgency of resolving the issue swiftly.

Impact Assessment

Impact assessment of supplier errors can significantly affect business operations, particularly in aspects such as product quality and delivery timelines. An erroneous shipment of raw materials, for instance, may result in increased production downtime, affecting profitability. Depending on the severity of the error, costs can escalate as businesses may need to reorder materials from suppliers like Just-In-Time (JIT) manufacturers, leading to delays of several days or even weeks. In financial terms, unexpected expenses due to quality issues can reach thousands of dollars, impacting profit margins. Furthermore, customer satisfaction may decline if product delivery timelines are missed, potentially affecting future sales and long-term brand loyalty. It is crucial for organizations to implement a thorough error reporting procedure to assess risks and mitigate negative impacts efficiently.

Desired Resolution or Action

In the context of supplier error reporting, the desired resolution or action focuses on correcting discrepancies and improving future performance. Timely communication (within 24 hours of error detection) is crucial, including detailed documentation of the specific issues, such as defective goods or misdelivered items. Immediate corrective actions (like replacements or refunds) should be clearly outlined, ensuring accountability and transparency. The implementation of root cause analysis (an investigation to identify underlying issues) is essential for preventing recurrence. Establishing a follow-up mechanism, such as regular performance review meetings (scheduled monthly), can enhance collaboration and drive continuous improvement between supplier and client relationships.

Payment and Return Instructions

The supplier error reporting procedure outlines essential steps for addressing discrepancies in delivered goods, including payment and return instructions. When an error occurs, such as incorrect items delivered or damaged products received, immediate notification to the supplier (including date, order number, and specific details of the issue) is crucial. Return shipments must follow the guidelines specified: procurement documentation, return authorization requests, and the use of designated carriers for shipping. Payment adjustments translate into credit notes issued for defective items, while proper documentation of transactions ensures timely resolution of financial discrepancies. Adhering to these protocols, including a response window (usually within 14 days) for reporting issues, streamlines communication and fosters stronger supplier relationships.

Contact Information for Further Communication

In the supplier error reporting procedure, accurate contact information ensures clear and efficient communication regarding issues that arise during the supply chain process. Key entities include supplier names such as ABC Manufacturing and DEF Logistics, along with essential contact details like email addresses (e.g., support@abcmanufacturing.com), direct phone lines (e.g., +1-234-567-8901), and designated points of contact (e.g., John Doe, Procurement Manager). Establishing a centralized communication channel, such as a dedicated error reporting email (e.g., errors@deflogistics.com), allows for streamlined error resolution. Furthermore, all relevant stakeholders, including quality assurance teams and logistics coordinators, should have access to this information to facilitate prompt follow-up on reported discrepancies.

Comments