Are you looking to streamline your logistics operations and improve efficiency? In today's fast-paced world, automated logistics systems are revolutionizing how businesses manage their supply chains. These innovative solutions not only save time but also reduce costs and enhance overall productivity. If you're curious about how these systems can transform your operations, read on to discover more!

Personalization and recipient information

Automated logistics systems enhance operational efficiency through advanced software technology. Personalization features, such as recipient information (name, address, contact number), ensure customized communication for each package. For example, delivery notifications can be tailored to individual preferences, increasing customer satisfaction. In addition, geographic data (postal codes, landmarks) enables precise routing, reducing transit times. Tracking updates not only improve transparency but also empower recipients with real-time data on their shipments. Overall, these systems streamline processes, from warehousing to delivery, creating a seamless experience for both businesses and consumers.

Clear subject and purpose

Automated logistics systems optimize supply chain processes through advanced algorithms and robotics. These systems can significantly reduce operational costs by utilizing artificial intelligence (AI) to manage inventory levels and forecast demand accurately. For instance, warehouse automation relies on robotics technology, such as Automated Guided Vehicles (AGVs), which can transport goods within the facility with precision. Additionally, real-time tracking systems, like RFID (Radio-Frequency Identification), enhance visibility across the supply chain, enabling stakeholders to monitor shipments throughout their journey. Efficient routing software can also minimize delivery times, resulting in increased customer satisfaction and overall performance improvements.

Detailed logistics process outline

Automated logistics systems enhance supply chain efficiency through streamlined processes. Key components include warehousing, where robotics and automation manage inventory levels, reducing human error. For instance, automated guided vehicles (AGVs) transport goods throughout facilities, ensuring timely movement. In the packing stage, systems utilize machine vision and AI algorithms to optimize packaging sizes, minimizing material waste. Distribution networks benefit from real-time tracking using barcodes and RFID technology, which improves delivery accuracy and transparency. Moreover, data analytics plays a crucial role in forecasting demands, allowing better resource allocation and inventory management across logistics hubs such as distribution centers located in key trade regions like Los Angeles or Rotterdam. Lastly, integration with transportation management systems ensures efficient routing, thereby reducing operational costs and transit times, ultimately enhancing customer satisfaction.

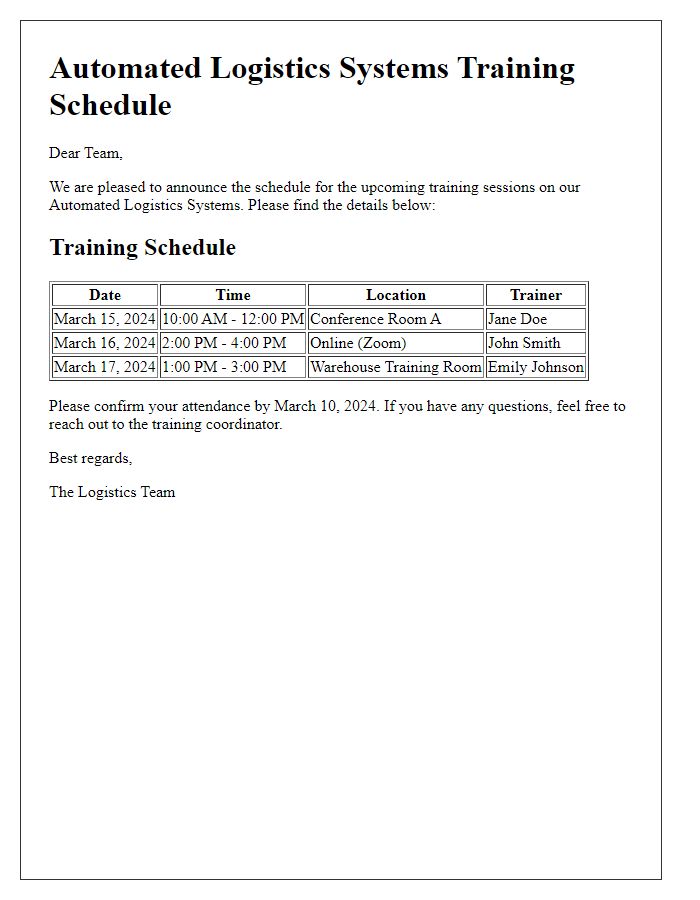

Automation technology description

Automated logistics systems utilize advanced automation technology, such as robotics and artificial intelligence, to enhance the efficiency of supply chain operations. These systems incorporate autonomous mobile robots (AMRs) that navigate warehouses, transporting goods swiftly between locations. The integration of real-time data analytics enables optimal inventory management, minimizing stockouts and overstock situations. Automated sorting systems, using machine vision technology, identify and categorize items based on size, shape, or barcode, streamlining the order fulfillment process. Furthermore, the use of automated guided vehicles (AGVs) can reduce human labor costs by up to 30% and significantly decrease error rates in order processing. These technologies not only enhance operational efficiency but also contribute to a more reliable and scalable logistics infrastructure, capable of adapting to fluctuating market demands.

Benefits and contact information

Automated logistics systems offer numerous advantages, enhancing efficiency and accuracy in supply chain management. Key benefits include increased operational efficiency, with automation streamlining processes like inventory management and order fulfillment, often resulting in a reduction of lead times by up to 30%. Error rates in order picking and shipping can drop significantly, sometimes as low as 0.5%. Moreover, advanced technologies such as robotic process automation (RPA) and artificial intelligence (AI) enable real-time tracking and predictive analytics, leading to better decision-making. Cost savings are notable as well, with some organizations experiencing up to a 20% reduction in labor costs due to decreased reliance on manual processes. For inquiries, reach out through our contact channels: email at info@logisticsautomation.com or phone at (123) 456-7890.

Comments