Are you preparing to return equipment and feeling a bit overwhelmed? You're not alone! Having a clear checklist can simplify the process and ensure that nothing is overlooked. In this article, we'll provide you with a handy equipment return checklist to make your transition smootherâread on to get started!

Equipment Identification

The equipment identification process is crucial for asset management within organizations, ensuring the accurate tracking and return of items such as laptops, projectors, or specialized tools. Each piece of equipment typically carries a unique identification number, which may be formatted as a serial number, bar code, or RFID tag, assigned during the initial inventory registration process. Organizations often implement systems such as Asset Management Software (AMS) to maintain records of equipment status, location, and user history. Properly documenting equipment identification not only streamlines the return process but also safeguards company resources, minimizing loss or misplacement. This attention to detail can significantly enhance operational efficiency and accountability among team members.

Condition Assessment

Return of electronic equipment involves a detailed condition assessment to ensure optimal functionality. Items such as laptops (e.g., Dell Latitude series) should be checked for physical damage, including scratches or dents on the casing, and functionality of the keyboard and trackpad. Cable connections, such as USB and HDMI ports, must be inspected for wear or damage. Additionally, battery health should be evaluated, with a focus on charge cycles and overall capacity, typically measured in milliamp hours (mAh). Accessories like chargers should also be verified for compatibility and proper operation, with emphasis on voltage ratings (e.g., 19.5V for laptops). Documentation may include serial numbers, purchase dates, and warranty statuses, vital for tracking and accountability.

Accessories and Components

The equipment return checklist for accessories and components should include essential items such as cables (HDMI, USB, and power cables) which facilitate connectivity between devices. Check the functionality of adapters (such as VGA and Thunderbolt) required for different presentation setups in conference rooms. Verify the inclusion of protective cases and carrying bags, which are crucial for safeguarding equipment during transit. Inspect the condition of spare batteries and chargers, ensuring they are compatible with the equipment models in question. Lastly, examine any user manuals or installation guides, essential for understanding operational procedures and troubleshooting methodologies. Documenting the return of all these components ensures accountability and proper equipment management.

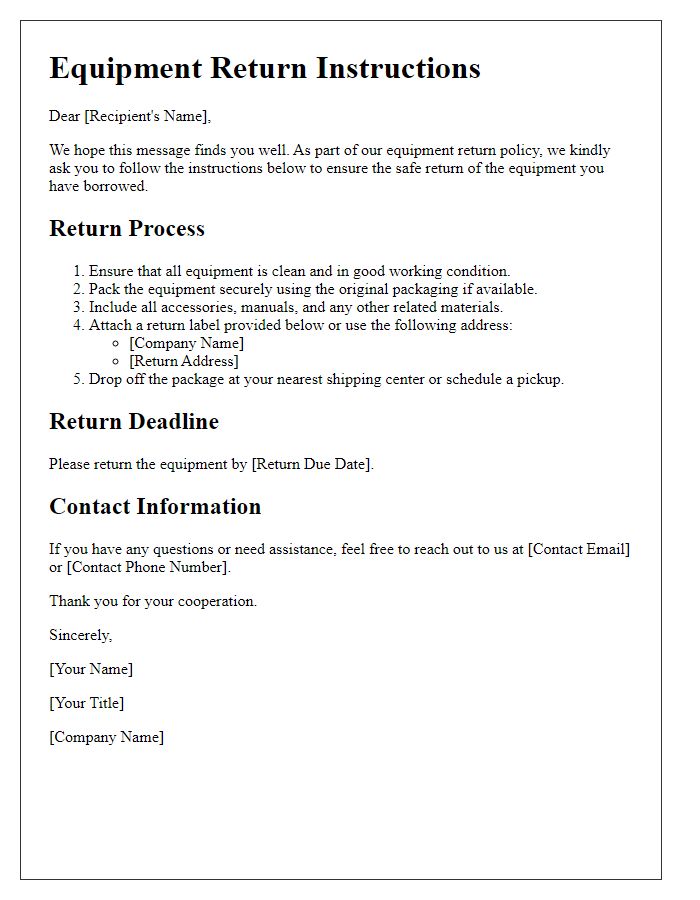

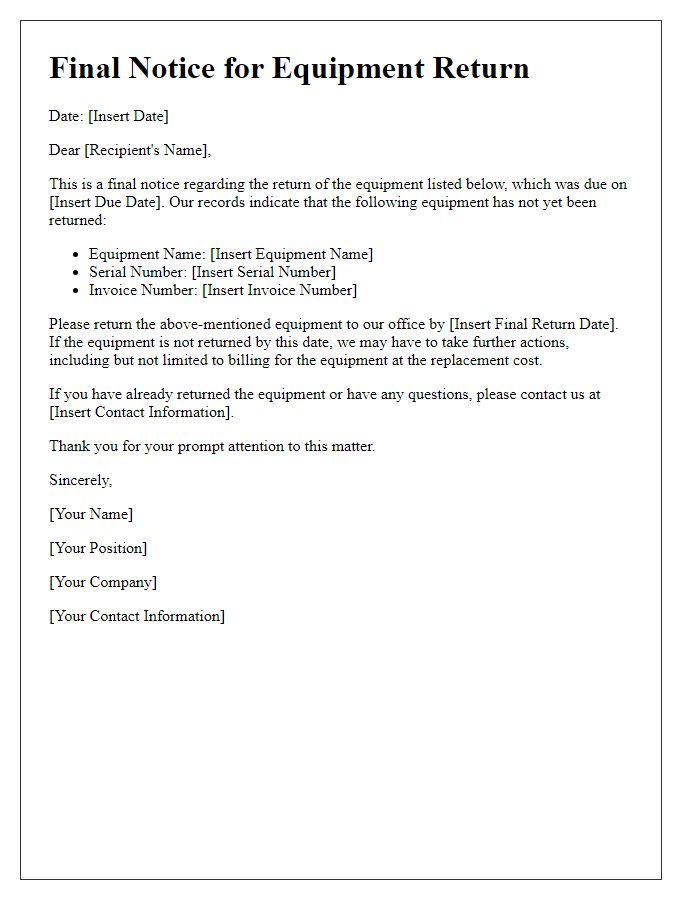

Return Instructions

An equipment return checklist is essential for ensuring a smooth and organized return process for items such as laptops, cameras, or other technical devices. Start with a clear header indicating "Equipment Return Checklist" followed by a list of items to be returned, including model names, serial numbers, and condition notes (e.g., functional, damaged). Include specific return instructions, detailing the method of return (in-person drop-off, shipping labels) and any deadlines (e.g., within 14 days from the last use). Additionally, specify any documentation required, such as a signed return form or proof of ownership. Finally, provide contact information for questions or concerns, ensuring all communication points are accessible for returning parties.

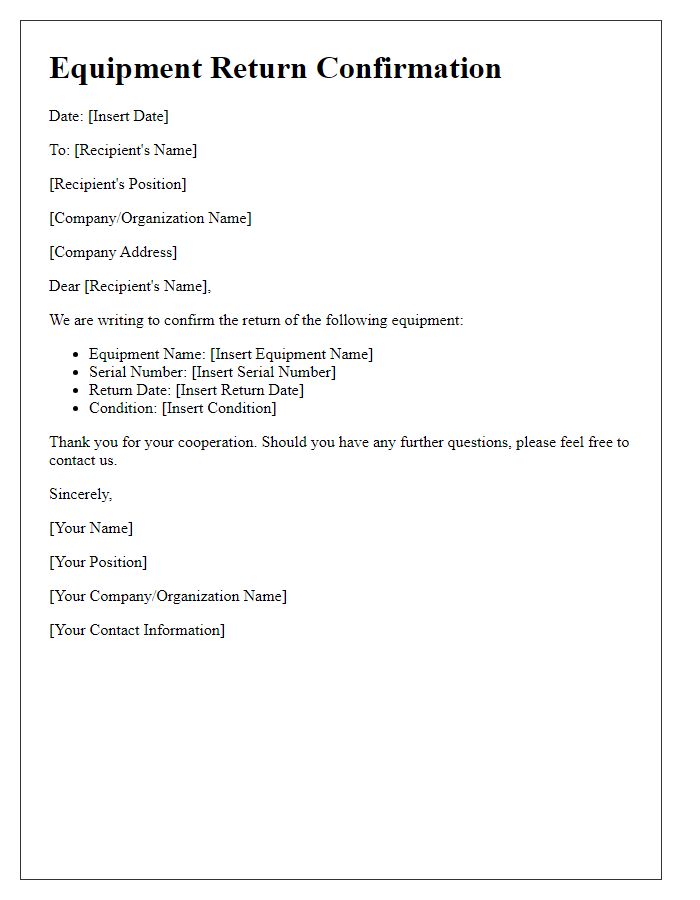

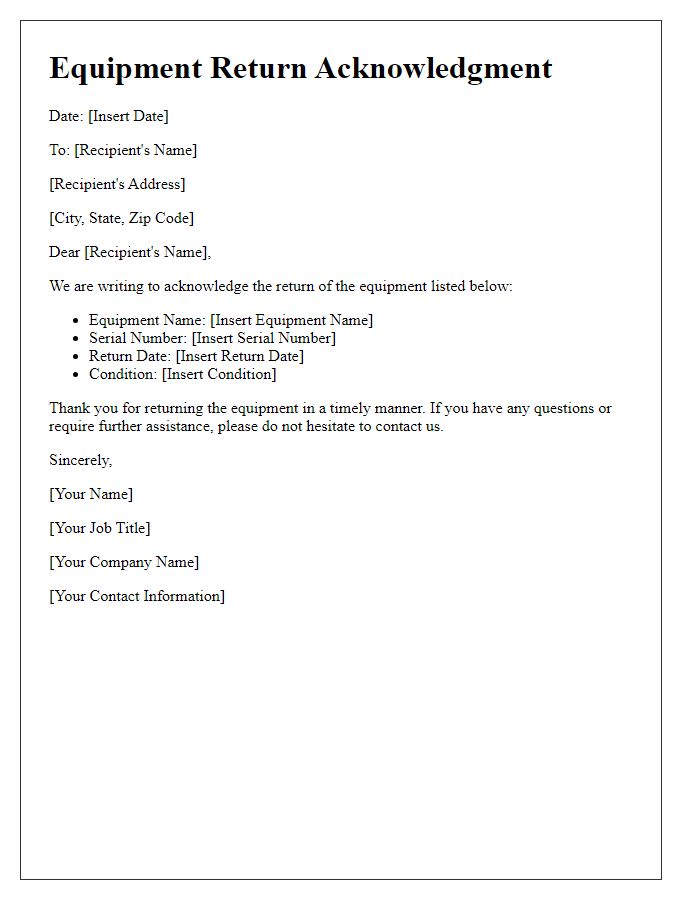

Signature and Acknowledgment

The equipment return checklist serves as a vital document in asset management for organizations, ensuring accountability during inventory processes. Each returned item, such as laptops from brands like Dell or HP, undergoes inspection to verify functionality and condition. Key components noted include serial numbers and model details, which aid in tracking assets effectively. The acknowledgment section requires signatures from both the returning employee and the receiving personnel, confirming the handover date and condition of equipment at the time of return. This process helps maintain an organized record for future reference, streamlining audits and inventory assessments.

Comments