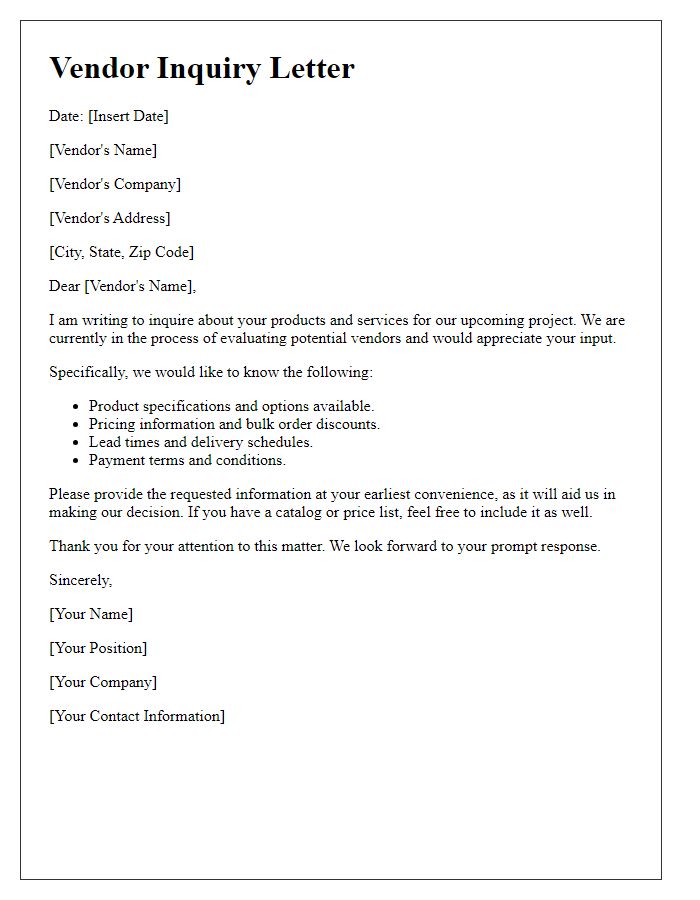

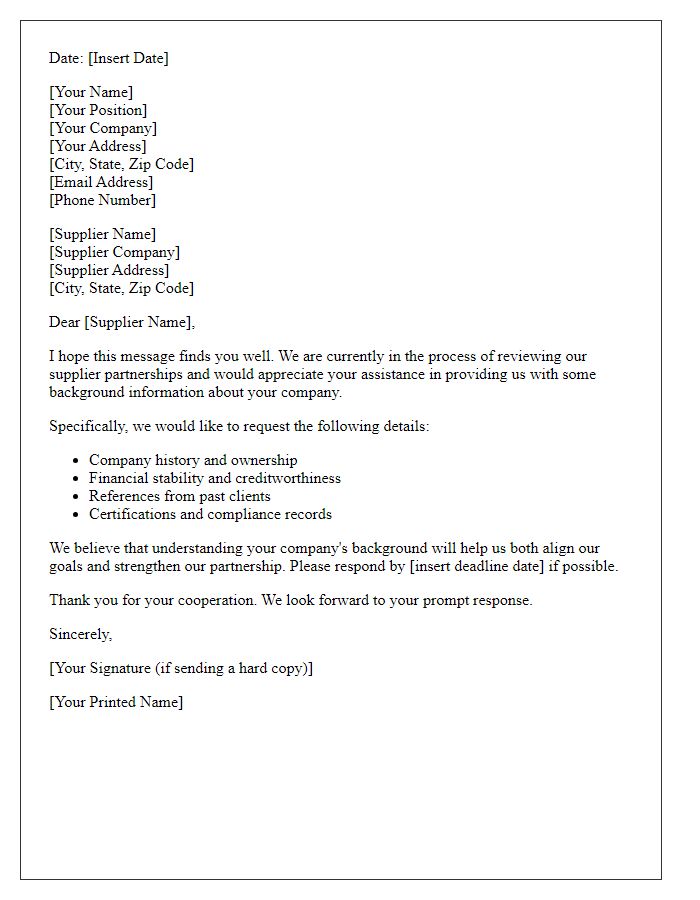

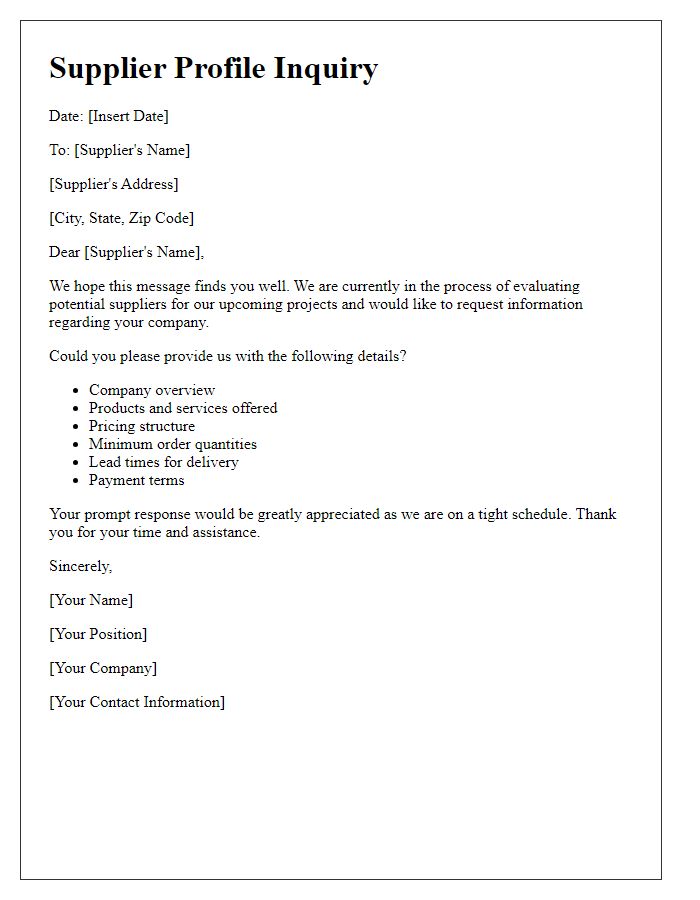

Are you looking to streamline your supplier communication? A well-crafted supplier information request letter can be your key to ensuring you have all the necessary details to make informed decisions. By asking the right questions and requesting essential documents, you can establish a solid foundation for a successful partnership. Curious about how to structure this important letter? Let's dive in and explore some effective templates!

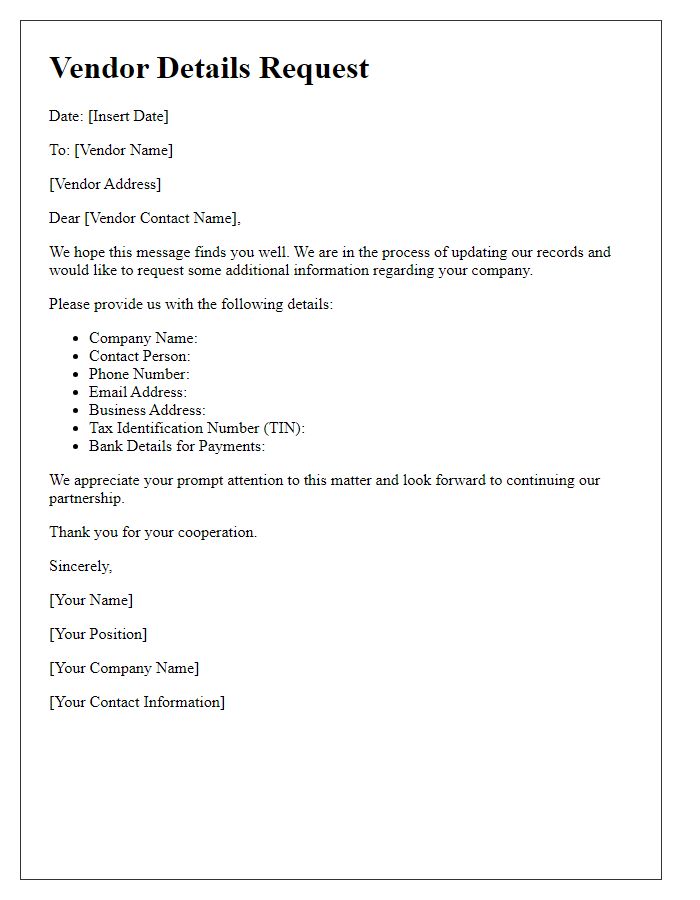

Supplier contact information

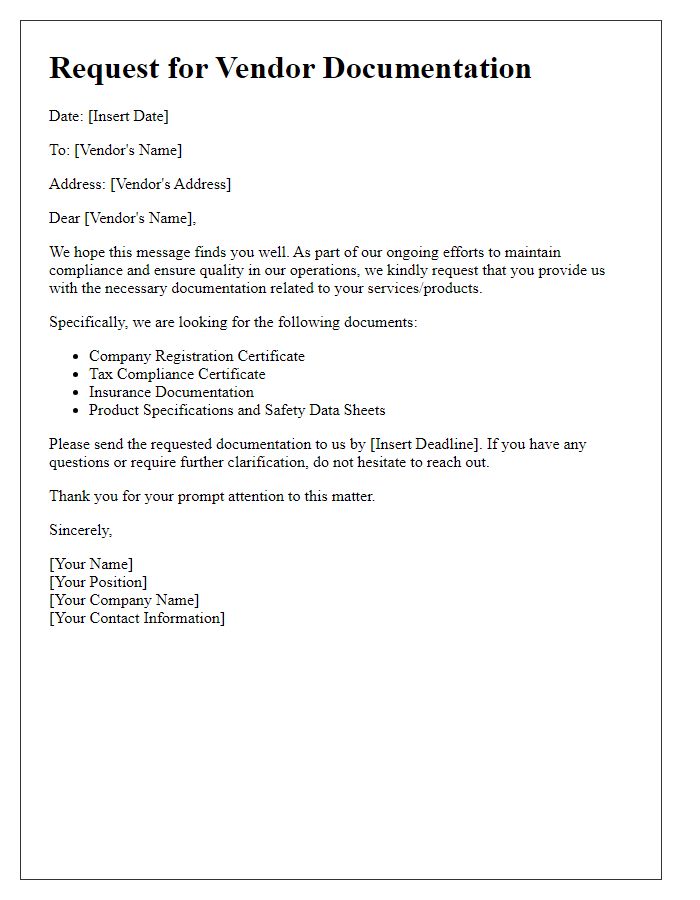

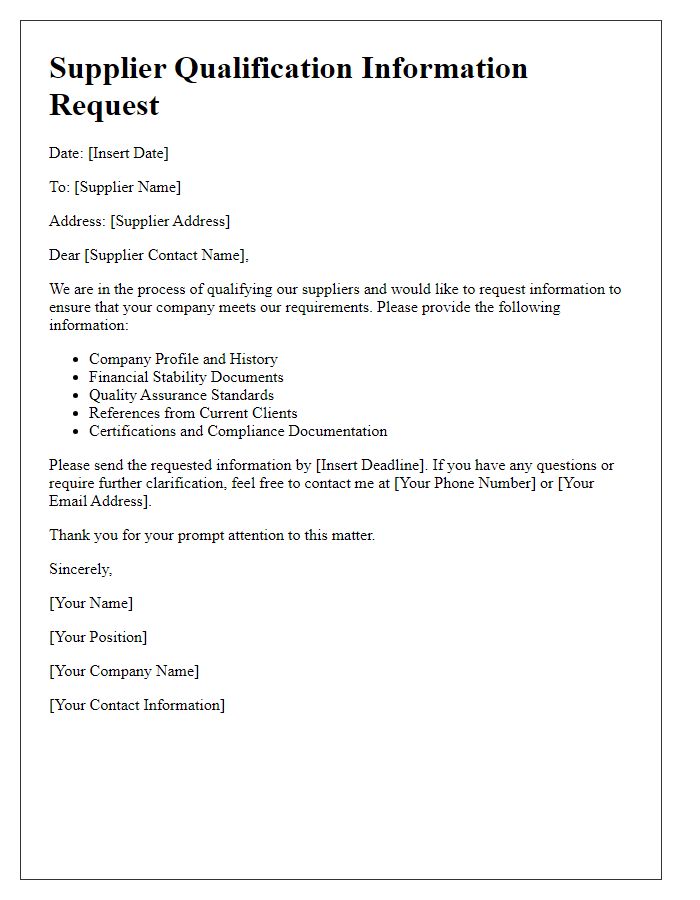

Acquiring accurate supplier contact information is essential for effective communication in supply chain management. Key details such as supplier name, address (including city and country), phone number, email address, and primary contact person are crucial for establishing reliable connections. Additionally, knowledge of the supplier's business hours, areas of specialization, and available certifications (such as ISO or industry-specific standards) can enhance collaboration. Maintaining an updated database of this information helps streamline procurement processes and ensures timely responses to inquiries or issues that may arise during the course of business.

Product or service details

Inquiries regarding supplier service details are crucial for maintaining quality standards and ensuring product efficiency. Comprehensive product specifications, such as dimensions, materials, and operational functionalities, should be requested to assess compatibility with existing inventory. Additionally, service agreements, including maintenance schedules and warranty duration, are significant for evaluating long-term relationships. Timely feedback about delivery schedules and pricing structures can greatly influence procurement decisions. Engaging with suppliers from regions like Southeast Asia or Europe can provide insights into diverse market practices and emerging trends. Careful consideration of these elements can enhance supply chain effectiveness and promote successful collaboration.

Pricing and payment terms

A supplier information request focuses on pricing structures and payment terms essential for procurement processes. Specific details may include product categories, such as electronics (often priced per unit or wholesale) or raw materials (including per ton or cubic meter pricing). The request may specify quantities required, potentially affecting bulk pricing options. Payment terms, vital elements in negotiations, typically cover conditions like net 30 or net 60 payment schedules, early payment discounts, and acceptable payment methods (credit, wire transfer, etc.). Clear communication of expectations regarding delivery timelines is important, as these can vary between suppliers and may impact cash flow management.

Quality assurance and certifications

High standards in supply chain management necessitate comprehensive quality assurance and certification details from vendors. Documentation of quality management systems, such as ISO 9001 (International Organization for Standardization), ensures products meet stringent global benchmarks. Certifications relevant to specific industries, like FDA approval (Food and Drug Administration) for food and pharmaceutical products, guarantee adherence to safety and regulatory standards. Additionally, details regarding any third-party testing, such as UL (Underwriters Laboratories) certification for electronics, provide further validation of product reliability. Timely submission of this information is crucial to maintaining operational integrity and consumer trust in products delivered to clients.

Delivery and logistics information

Delivery logistics play a crucial role in supply chain management, affecting the timely receipt of goods from suppliers (entities that provide products or services). Efficient delivery systems, such as just-in-time (JIT) inventory practices or proactive tracking methodologies, ensure that essential materials arrive at manufacturing facilities like automotive plants or food processing factories on schedule. Specific information, such as lead times (the duration from order placement to delivery) and shipping methods (air freight, ocean freight, etc.), directly influences production schedules and inventory management strategies. Geographical considerations, including distances from supplier locations to distribution centers, can also impact costs and delivery times. Understanding these logistics helps businesses optimize their operations and enhance customer satisfaction by minimizing delays and ensuring smoother transitions in their supply chains.

Comments