Are you looking to craft a compelling business proposal for your industrial project? Writing a persuasive letter can make all the difference in securing support and resources. In this article, we'll guide you through essential elements to include in your proposal letter, ensuring that it captivates and informs your audience. So, let's dive in and explore how to create a winning letter that stands out!

Project Overview and Objectives

The industrial project focuses on the development of a state-of-the-art manufacturing facility located in the Midwestern United States, specifically in Ohio, renowned for its skilled workforce and favorable logistics. The primary objective of this initiative is to enhance production efficiency by 30% within the first year of operation, utilizing innovative automation technologies such as robotics and AI-driven quality control systems. This project aims to create 200 new jobs, contributing to local economic growth while meeting the increasing demand for sustainable products in the automotive sector. Additionally, the facility will incorporate eco-friendly practices, reducing carbon emissions by 25% compared to traditional manufacturing processes, aligning with industry standards and regulations set for 2025. The successful completion of this project will not only establish a benchmark for manufacturing excellence but also reinforce the company's commitment to sustainability and community development.

Technical Specifications and Plans

A comprehensive industrial project proposal must include detailed technical specifications and strategic plans to ensure clear communication of objectives and methodologies. Technical specifications encompass critical components such as machinery capabilities (e.g., power ratings in kilowatts, operational speeds in revolutions per minute), materials needed (e.g., types of steel, quality grades), and compliance standards (e.g., ISO 9001 certifications). Plans should outline project phases, including timelines with milestones (e.g., initial site inspections on March 15, 2024), resource allocation (e.g., labor hours, equipment usage), and risk management strategies (e.g., contingency plans for supply chain disruptions). Clear graphs and charts depicting workflows and organizational structures (e.g., a Gantt chart detailing project timelines) can enhance understanding. Additionally, including a budget overview illustrating estimated costs for each project segment (e.g., raw materials, labor, overhead) will provide stakeholders with a transparent financial framework.

Budget and Financial Projections

A comprehensive budget is essential for the industrial project submitted for consideration in 2023, detailing the estimated costs and expected financial returns from investment. The total budget is projected at $2 million, encompassing various expenses such as raw materials (estimated at $600,000), labor costs (approximately $800,000 for skilled and unskilled workers), and equipment procurement (around $400,000 for machinery and tools). Operational expenses (estimated at $200,000) include utilities, maintenance, and overhead costs, while a contingency fund of $100,000 is allocated for unforeseen expenses. Financial projections indicate a potential revenue of $3 million in the first year, with an anticipated growth rate of 15% annually over the next five years, resulting in a projected net profit margin of 25% by the end of year five, effectively showcasing a strong return on investment for stakeholders involved in this industrious venture.

Timeline and Milestones

A comprehensive project timeline outlines critical milestones for industrial projects, ensuring efficient management and tracking. The initiation phase lasts approximately one month, where objectives are defined, and resources are allocated. Following this, the planning phase spans two months, involving risk assessment and budget approvals. The execution phase, typically six months, focuses on construction and installation activities at the designated site, such as a manufacturing facility or warehouse. Key milestones during execution include the completion of foundational work by week eight and the installation of machinery and equipment by week twenty. The monitoring phase, lasting three months, ensures adherence to quality standards and adherence to safety regulations. Finally, the project closure phase, which takes about one month, involves final inspections, project handover, and documentation of lessons learned. This structured timeline enhances project visibility and accountability among stakeholders.

Team Expertise and Experience

The team behind the industrial project proposal boasts a wealth of expertise and experience in engineering, project management, and operations within the manufacturing sector. Key members hold advanced degrees in Mechanical Engineering from renowned institutions like Massachusetts Institute of Technology (MIT) and Stanford University, each with over 15 years of professional experience. Notably, the project manager successfully oversaw a $10 million production facility expansion, optimizing workflow and diversifying output. Additionally, the lead engineer has a proven track record in implementing Industry 4.0 solutions for increased automation, resulting in a 30% efficiency improvement in previous projects. Collectively, this team has completed over 50 successful projects across North America and Europe, demonstrating a strong commitment to innovation and quality in industrial operations.

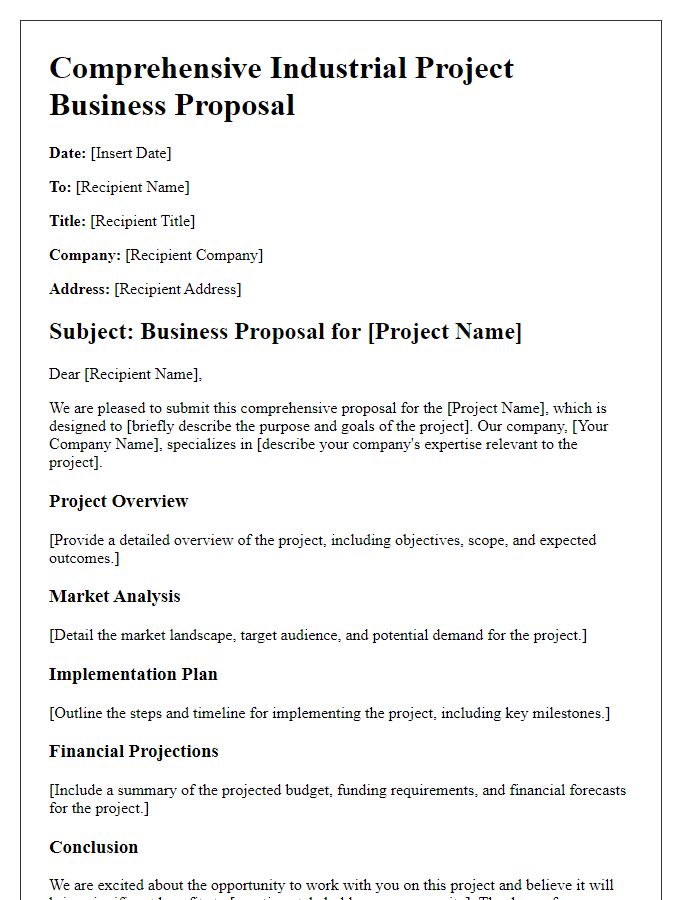

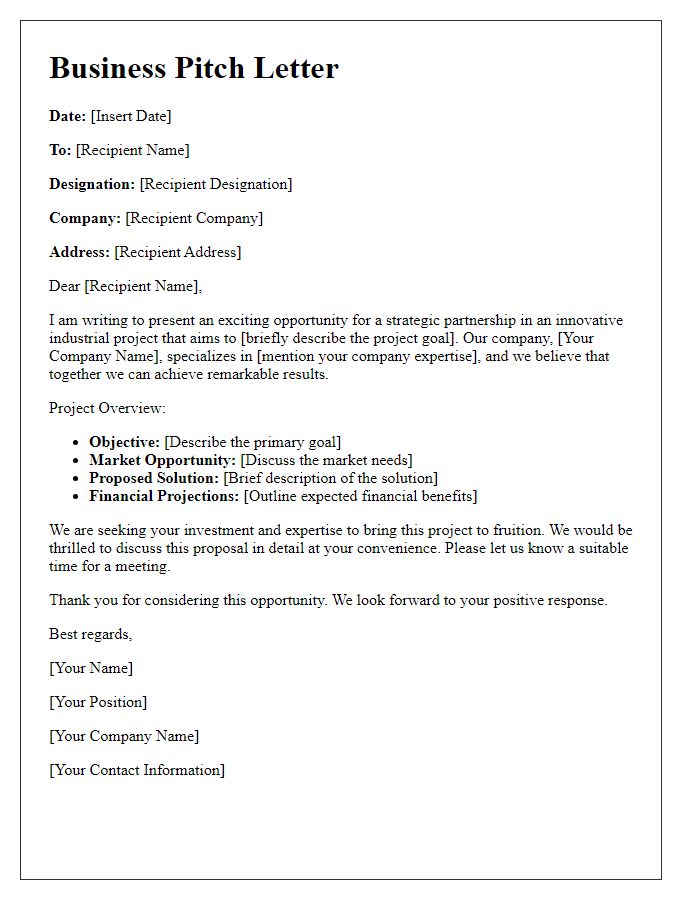

Letter Template For Industrial Project Business Proposal Samples

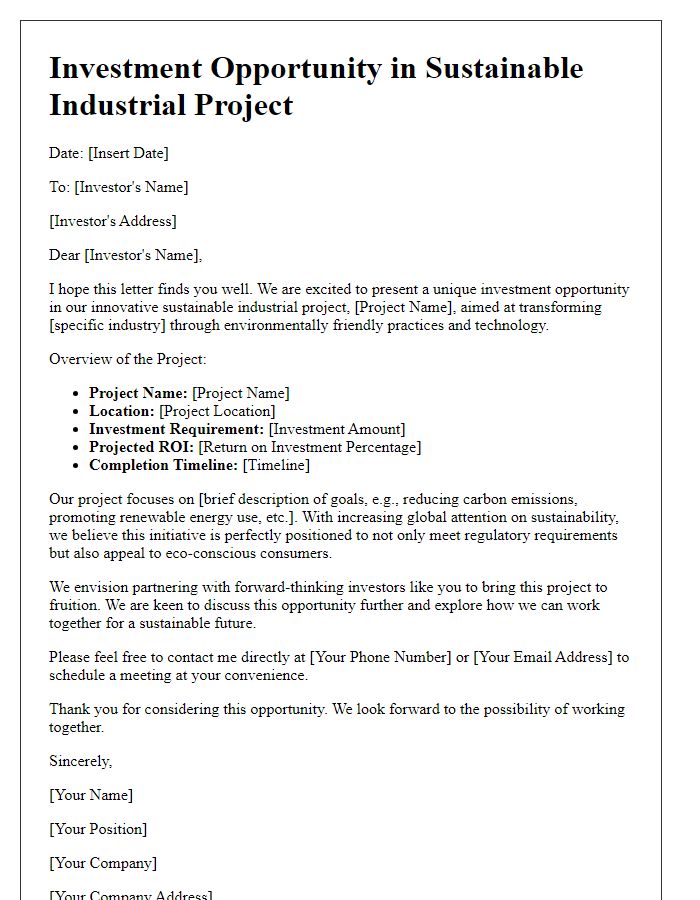

Letter template of sustainable industrial project investment opportunity

Comments