Are you looking to elevate your manufacturing capabilities? A strategic partnership can be the catalyst for innovation and growth that your business needs. By collaborating with like-minded companies, you can leverage shared resources and expertise, opening doors to new markets and solutions. Join us as we explore the benefits of forming a manufacturing partnership and how it can transform your operations!

Company's Mission and Vision Alignment

A successful manufacturing partnership can significantly elevate productivity and innovation when aligned with the core values and aspirations of both companies. The mission, which encapsulates the fundamental purpose, and the vision, representing the long-term goals, create the foundation for collaboration. For instance, a company focusing on sustainable practices may prioritize eco-friendly materials in production, reflecting a commitment to environmental stewardship. This alignment fosters mutual growth and encourages the implementation of innovative solutions, such as adopting advanced technologies like automation or utilizing smart supply chain systems to enhance efficiency. Ultimately, a shared mission and vision not only drive operational synergy but also foster a strong partnership built on trust and shared objectives.

Proposed Partnership Benefits

Forming a manufacturing partnership can yield numerous benefits for both parties involved. Cost savings (up to 20% reduction in production expenses) may be realized through shared resources and economies of scale, particularly in bulk procurement of raw materials such as steel or plastic. Improved product quality can emerge from collaborative investments in advanced technology and machinery, enhancing precision and reducing defect rates. Access to larger markets can be achieved by leveraging combined distribution networks, allowing for expanded reach and increased sales opportunities in regions like North America and Europe. Additionally, increased innovation may stem from the fusion of diverse expertise, which can lead to the development of new products or improved processes. Ultimately, this strategic alliance can foster long-term sustainability and profitability in the competitive manufacturing landscape.

Unique Selling Proposition (USP)

A unique selling proposition (USP) is a critical element in forming a successful manufacturing partnership by clearly defining the distinct advantages and benefits of collaboration. A manufacturer with advanced capabilities, particularly in automation technology and quality control processes, can significantly enhance production efficiency, primarily focusing on reducing lead times and minimizing defects. The unique processes, such as Just-In-Time (JIT) inventory management, exemplify how the partnership can adapt seamlessly to fluctuating market demands, thus ensuring timely delivery of goods. Sustainable practices, such as sourcing eco-friendly materials or implementing energy-efficient production methods, also underscore the commitment to environmental responsibility, appealing to a growing segment of conscientious consumers. Moreover, leveraging a robust supply chain network can facilitate cost savings and reliable sourcing of raw materials, enabling competitiveness in price while maintaining superior product quality.

Timeline and Milestones

A manufacturing partnership proposal outlines a clear timeline with specific milestones to ensure progress and accountability in the partnership. For instance, during the initial phase, a comprehensive feasibility study will be conducted over a three-month period, beginning in January 2024, assessing potential manufacturing capabilities and resource availability. Milestone One may involve securing necessary permits and approvals by April 2024, followed by Milestone Two, which involves establishing supply chain relationships by June 2024. In the subsequent phase, a prototype will be developed and tested by August 2024, with a dedicated team evaluating performance metrics and quality standards. The final milestone, targeting a full-scale production launch, is aimed for October 2024, ensuring that all processes are optimized and production goals are met for the upcoming holiday season. Regular progress reviews will occur monthly at the manufacturing facility in Detroit, Michigan, to monitor adherence to the timeline and adapt strategies as necessary to mitigate any risks that may arise.

Legal and Compliance Framework

A well-structured legal and compliance framework is essential for establishing robust manufacturing partnerships, ensuring adherence to industry standards and regulations. Key elements typically include comprehensive contracts outlining roles, responsibilities, and expectations between parties involved, such as manufacturers and suppliers. Compliance with local, national, and international regulations, such as ISO (International Organization for Standardization) standards, FDA (Food and Drug Administration) guidelines for health-related products, and environmental laws specific to manufacturing processes, plays a critical role in maintaining operational integrity. Implementing regular audits and assessments further safeguards against potential legal risks, promoting transparency and accountability. Additionally, intellectual property protections ensure that proprietary technologies or designs remain secure, fostering innovation within the partnership. Overall, an effective legal and compliance framework can significantly enhance the durability and success of manufacturing collaborations, leading to sustainable growth and mutual benefit for all stakeholders involved.

Letter Template For Manufacturing Partnership Proposal Samples

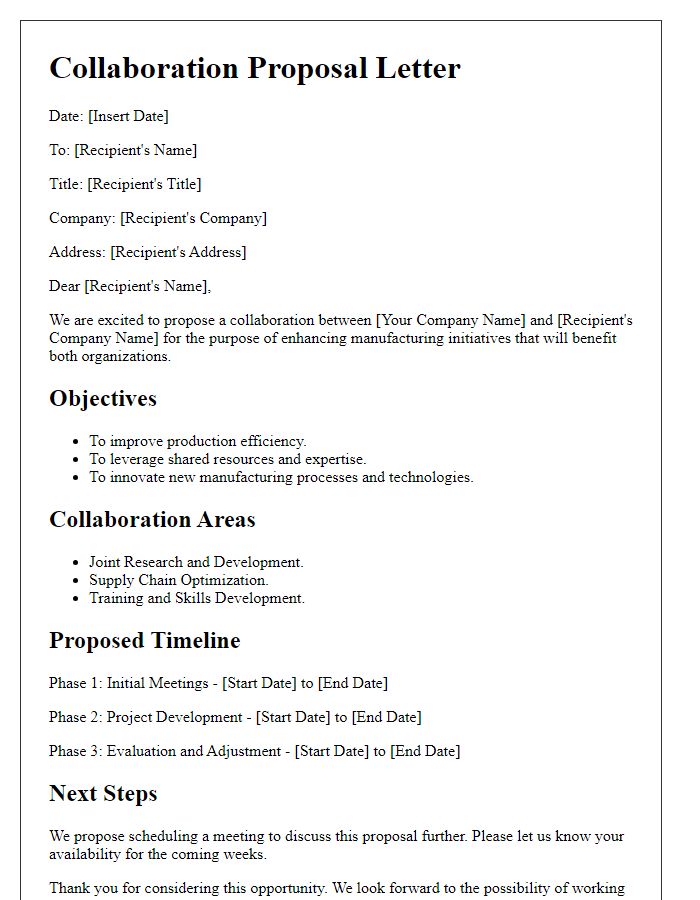

Letter template of strategic partnership invitation for manufacturing sector

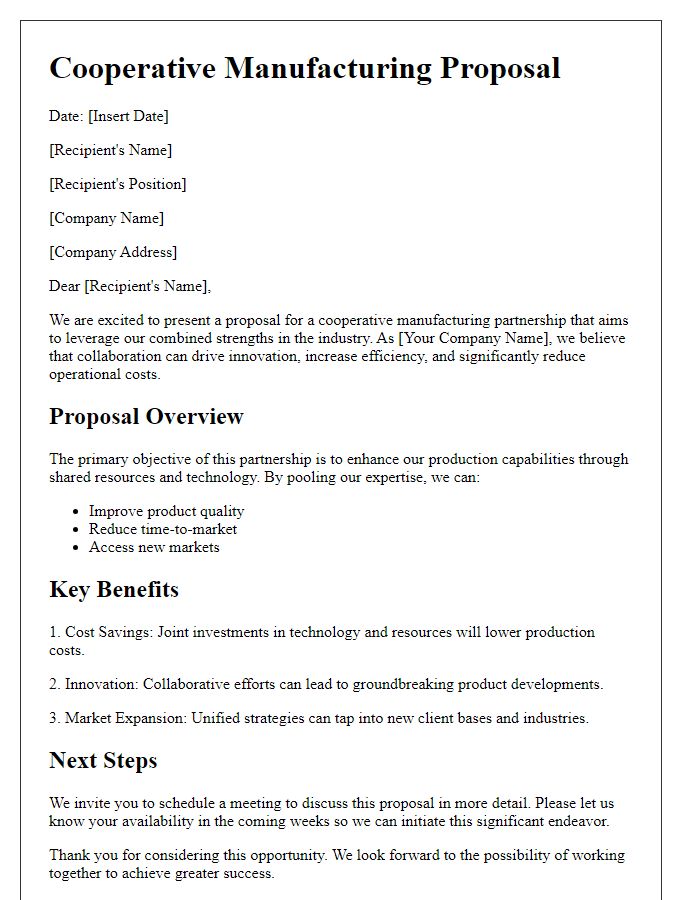

Letter template of manufacturing partnership inquiry for project collaboration

Letter template of production partnership suggestion for enhanced efficiency

Comments