In today's fast-paced business world, communication is key, especially when it comes to managing expectations with our partners. Recently, we encountered an unforeseen delay in our shipment process that we want to address directly with you. We understand how crucial timely deliveries are for maintaining our partnership, and we are actively working on a solution to expedite the situation. To learn more about the details and our plan moving forward, please continue reading.

Clear Subject Line

Unforeseen delays in shipment have affected the delivery schedule of our recent order (Order Number: 123456) from your company, ABC Logistics. Initial dispatch was scheduled for May 1, 2023, but logistical challenges at the primary distribution center in San Francisco have postponed the process. Current estimates suggest a new arrival date of May 15, 2023, impacting our supply chain and affecting subsequent commitments to clients. We appreciate your understanding and cooperation during this period, as we take necessary steps to mitigate the impact of this delay on our operations.

Empathetic Opening Statement

Supply chain disruptions have emerged as a significant challenge for businesses across the globe, influencing the timeliness of deliveries. Recent events, such as the Global Shipping Crisis occurring in 2021, have led to unprecedented delays in the transportation and logistics sectors. Ports, like the Port of Los Angeles, have experienced congested backlogs, causing shipping delays of several weeks. Additionally, factors such as labor shortages and increased demand for goods during key retail seasons have further complicated the situation. In this context, it is important to communicate clearly and compassionately with partners regarding shipment timelines while offering solutions to navigate these challenges together.

Detailed Explanation of Delay

Unexpected shipment delays can significantly impact supply chain dynamics, particularly during peak seasons or product launches. In this instance, the logistics company, Global Freight Solutions, reported a three-week setback due to severe weather conditions in the Midwest region of the United States, which resulted in road closures and transportation interruptions. Additionally, port congestion at the Port of Los Angeles, caused by an unexpected surge in cargo volume, further exacerbated the situation, delaying customs clearance processes. Furthermore, supplier delays from overseas partners in Asia due to production halts attributed to facility upgrades have compounded the overall issue. The revised delivery schedule now aims for arrival by late October 2023, ensuring that all stakeholders are informed and prepared for updated inventory management strategies.

Apology and Acknowledgement of Impact

Shipment delays can significantly impact business operations and partnerships, particularly in sectors such as retail and manufacturing. Recent logistical disruptions caused by supply chain issues, including global port congestion and transportation shortages, have affected timely deliveries across various industries. For example, the Port of Los Angeles, one of the busiest ports in North America, has experienced record backlogs, which has resulted in extended wait times for containers. These delays inevitably affect inventory levels, lead to stockouts, and can damage customer relationships. Acknowledging the impact of such delays on business partners is crucial for maintaining transparency and trust. Strengthening communication channels and setting realistic expectations about future shipments can mitigate frustration and foster collaboration in overcoming these challenges.

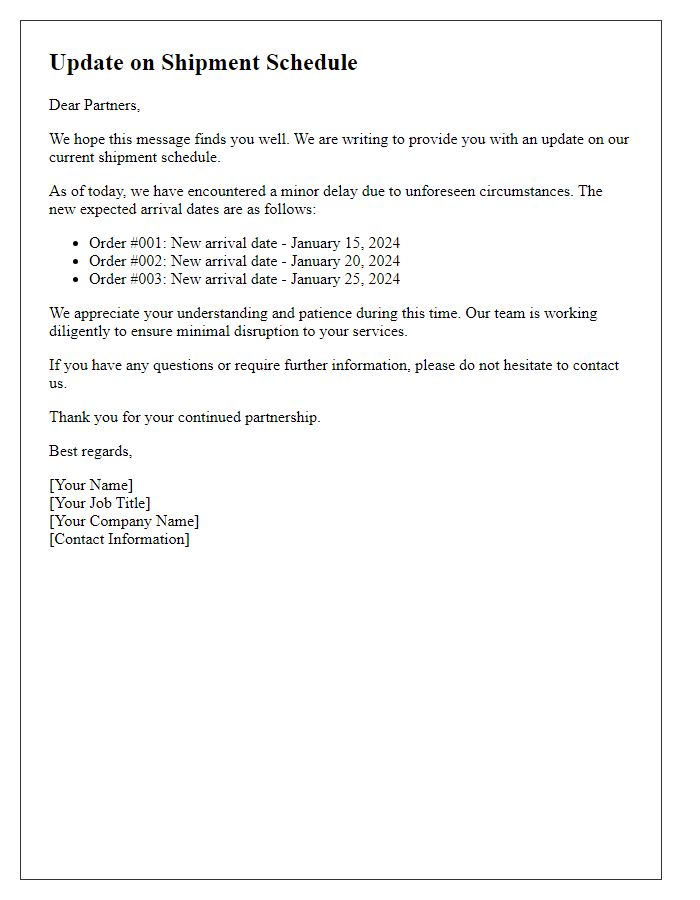

Proposed Solution and Timelines

Recent shipment delays have impacted the distribution schedules of several businesses, particularly in the manufacturing sector. Such delays can arise from various challenges, including supply chain disruptions, increased demand for raw materials, or logistical issues at shipping ports, such as the Port of Los Angeles, which faced significant congestion in 2021. Proposed solutions often involve enhancing communication with suppliers, implementing advanced forecasting tools to anticipate potential shortages, and negotiating expedited shipping options. Timelines for recovery may vary; however, a realistic approach could involve immediate measures to mitigate further delays, with a target to resume normal operations within six to eight weeks. Collaborative planning sessions with partners can streamline processes and ensure transparency throughout the timeline adjustment.

Letter Template For Explaining Business Partner Shipment Delay Samples

Letter template of notification regarding shipment delay for business partners

Letter template of explanation for postponed delivery to business associates

Comments