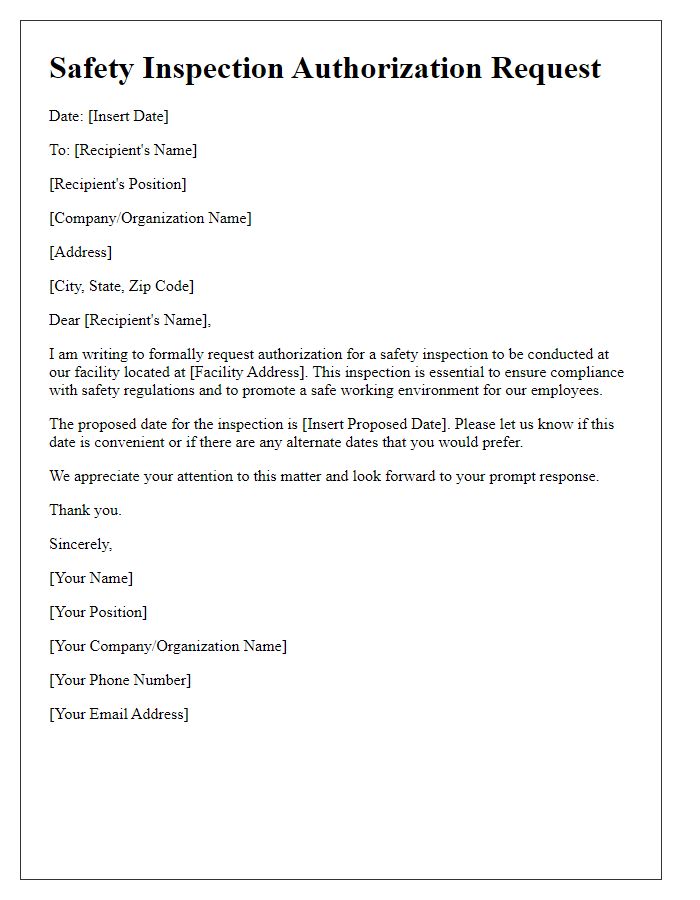

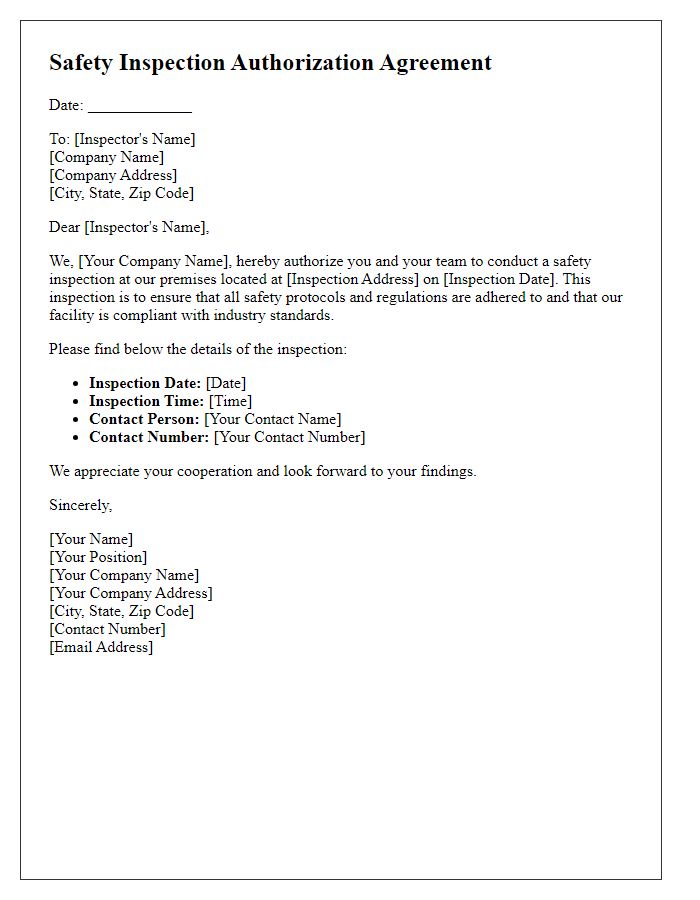

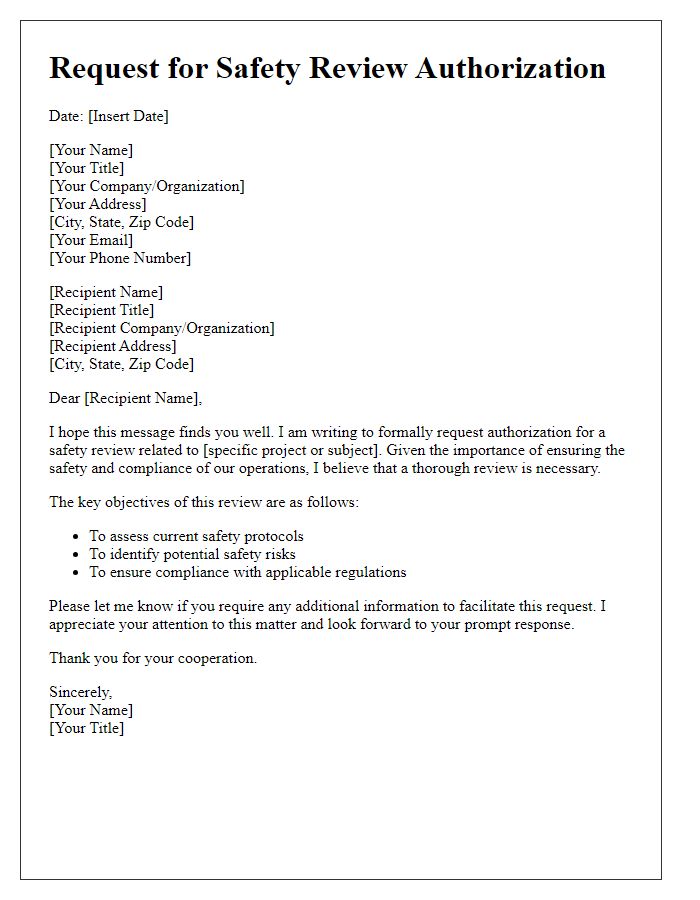

Are you looking to streamline your safety inspection process? It's essential to have a well-structured authorization letter that clearly conveys your intent and ensures compliance with safety regulations. This template not only simplifies the process but also emphasizes the importance of safety standards within your organization. Join us as we explore the key elements of crafting an effective safety inspection authorization letterâread on to learn more!

Company name and contact information

The preparation for a safety inspection authorization requires a focus on clarity and professionalism. The company name, such as "ABC Industries Ltd.," should be prominently displayed at the top, followed by essential contact information, including a physical address (1234 Industry Way, Suite 100, Springfield, IL 62701), a phone number (555-0123), and an email address (contact@abcindustries.com). Including a direct point of contact, such as the Safety Officer's name (John Doe) along with their title and phone number further enhances communication efficiency. Additional details might include the date of the authorization request and the specific nature of the inspection, such as "annual safety compliance inspection," ensuring that all relevant parties have a clear understanding of the context and purpose of the inspection.

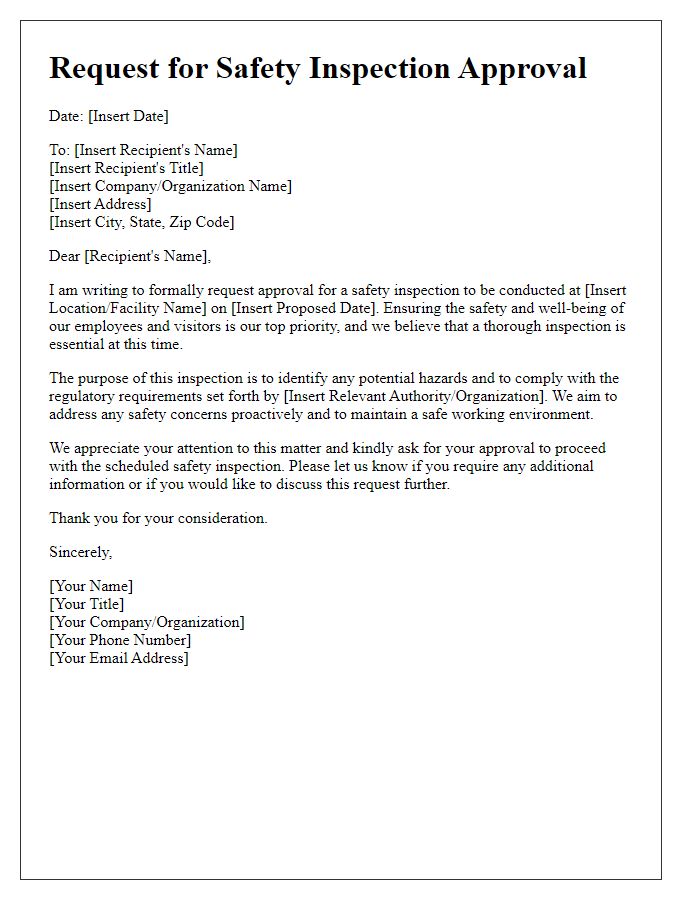

Authorized personnel details

A safety inspection authorization requires clear identification of authorized personnel along with their roles in the inspection process. This includes details such as full names, job titles, and contact information. Each individual's responsibilities should be specified, such as conducting the inspection, documenting findings, and implementing corrective actions. Additionally, mention any certifications or qualifications that enhance their capability to assess compliance with safety regulations. The location of the inspection, such as a specific facility or site, should also be highlighted, ensuring that each authorized personnel is aware of their designated area of responsibility during the safety evaluation. Collectively, these details provide clarity and accountability in the safety inspection process.

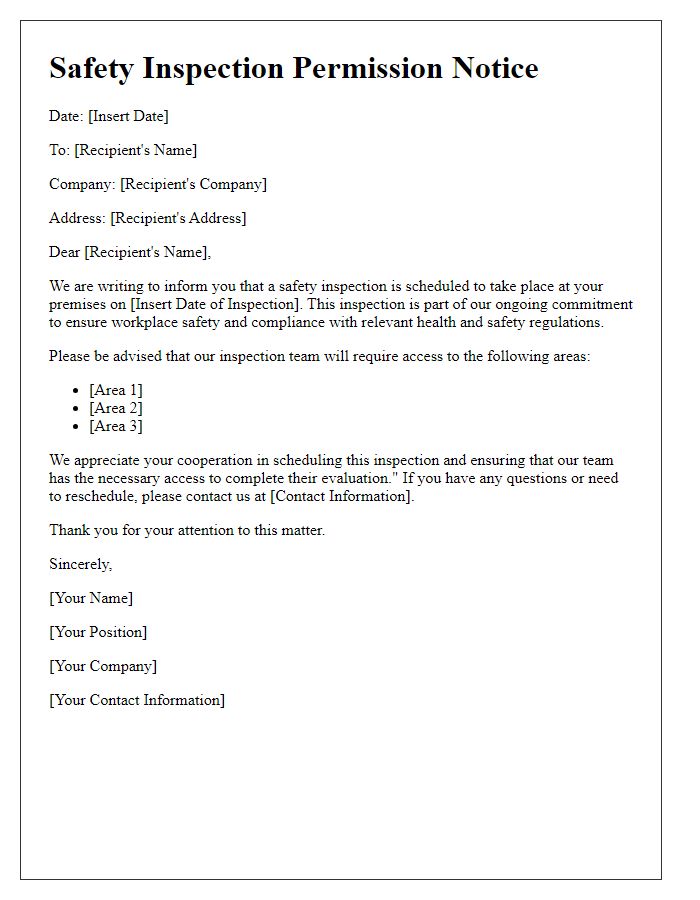

Scope of inspection and specific areas

A safety inspection authorization outlines the parameters of the inspection process, including the scope and specific areas to be evaluated within a facility. The primary focus may include critical locations such as machinery operation zones, chemical storage areas, and emergency exits. These regions must adhere to safety regulations mandated by agencies like OSHA (Occupational Safety and Health Administration). Inspection scope could encompass evaluating potential hazards, ensuring proper safety gear is available, and verifying employee training compliance. Documentation of findings will encapsulate areas such as electrical installations, fire safety measures, and ergonomic assessments to promote overall worker safety. This thorough examination fosters a secure work environment and adherence to legal standards, minimizing risks associated with workplace accidents.

Safety protocols and guidelines

Safety inspections adhere to established protocols and guidelines crucial for maintaining workplace safety across various industries. These protocols outline steps such as identifying hazards, conducting risk assessments, implementing corrective actions, and facilitating employee training on safety procedures. Regulatory entities like the Occupational Safety and Health Administration (OSHA) set specific standards, such as the necessity for regular inspections in high-risk environments like construction sites and manufacturing facilities. Documentation of these inspections, including checklists and incident reports, ensures compliance and helps track improvements over time. Utilizing personal protective equipment (PPE) per standards, such as ANSI specifications for eye and face protection, is paramount during safety evaluations to mitigate risks to inspectors and employees alike.

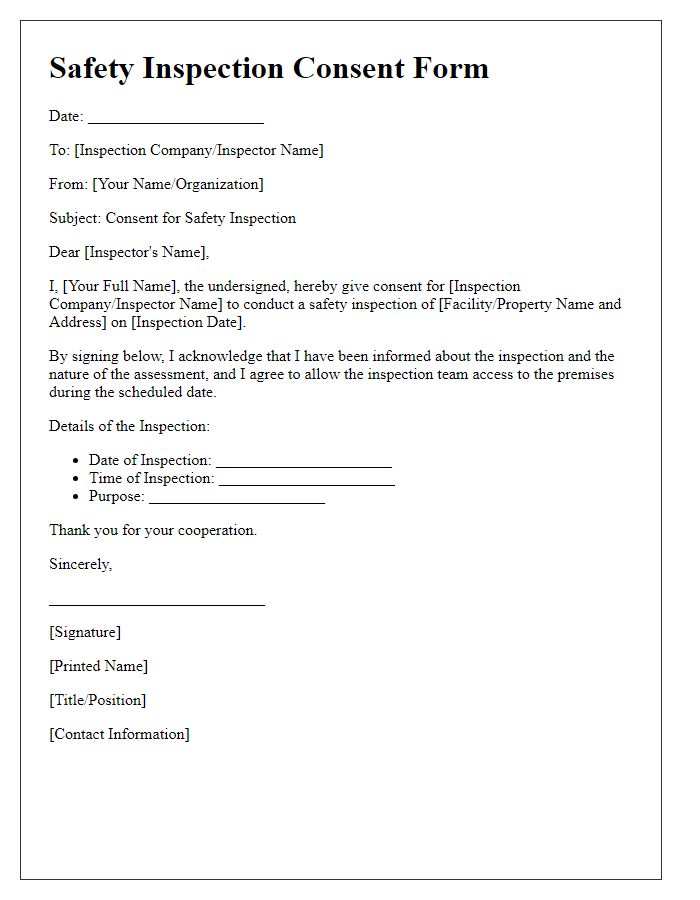

Duration and validity of the authorization

Safety inspection authorization, a critical component in workplace safety management, typically encompasses a specified duration and validity period defined by regulatory standards. This authorization remains effective for a predetermined period, often ranging from six months to one year, subject to local safety regulations and company policies. For instance, in industries such as construction (high-risk environments), continuous monitoring may necessitate more frequent inspections, while manufacturing may permit longer validity periods due to different operational risks. Following the expiration of the authorization, a renewal process usually requires re-evaluation of safety protocols and equipment compliance. Ensuring proper documentation during this period is crucial to maintain safety standards and meet legal obligations.

Comments