In today's fast-paced manufacturing world, recognizing the hard work and dedication of factory workers is more important than ever. These diligent individuals play a crucial role in the production process, ensuring that products meet both quality and efficiency standards. Acknowledging their efforts not only boosts morale but also fosters a sense of community and teamwork within the workplace. If you're curious about how to craft the perfect letter to express gratitude and appreciation, keep reading for some helpful tips!

Clear and concise recognition statement.

Dedicated factory workers contribute significantly to overall productivity and quality control within the manufacturing sector. Their consistent attention to detail and commitment to safety protocols ensure efficient operations in facilities like automotive plants or electronics factories. Recognizing individual achievements, such as an employee's ability to meet production targets or reduce waste by implementing lean manufacturing techniques, fosters a positive work environment. Acknowledgment of milestones, such as attending safety training sessions or completing quality assurance certifications, reinforces a culture of diligence and teamwork essential for success in fast-paced industries.

Specific examples of diligence and contribution.

Recognized factory workers display remarkable diligence through adherence to rigorous safety protocols, ensuring a secure working environment. For instance, during the machinery operation at XYZ Manufacturing in January 2023, a team member diligently maintained equipment, performing routine checks that enhanced operational efficiency, reducing downtime by 15%. Additionally, during the high-demand period of Q2 2023, staff members collaborated on a production line, consistently meeting or exceeding daily output goals (averaging 120 units per hour) while maintaining quality assurance standards. Moreover, individual contributions to streamlining processes resulted in a notable 20% reduction in waste materials, demonstrating a commitment to sustainability and cost-effectiveness. These specific examples highlight the invaluable diligence and contributions of factory workers in enhancing productivity and operational excellence.

Positive impact on team and company goals.

A dedicated factory worker significantly enhances team morale and aligns with company objectives, showcasing diligence in daily operations. Consistently meeting production targets, such as achieving 95% efficiency rates, exemplifies commitment to excellence. Engaging in collaborative efforts during team meetings, fostering a culture of open communication, encourages problem-solving and innovation among colleagues. Adherence to safety protocols not only ensures personal well-being, but also cultivates a secure work environment, reducing incidents and associated costs. Contributing to continuous improvement initiatives, like lean manufacturing techniques, demonstrates a proactive approach to optimizing processes and resource management, ultimately driving the company's bottom line toward greater success.

Expressions of gratitude and encouragement.

Factory workers exhibit remarkable diligence in achieving production goals consistently. Their dedication, often reflected in long hours and repetitive tasks, ensures that manufacturing timelines are met, particularly in high-demand environments such as automotive and electronics sectors. Recognizing excellence in teamwork, they contribute significantly to overall efficiency and output. Encouragement through recognition programs can enhance morale and productivity. Gratitude expressed through bonuses or additional time off fosters a positive workplace culture, directly impacting retention rates. In addition, training sessions empower workers with skills, further advancing their careers and benefiting the company.

Personalized closing with future prospects.

Factory workers in manufacturing industries often demonstrate diligence that significantly impacts productivity and team morale. A diligent factory worker consistently adheres to safety protocols, such as wearing proper personal protective equipment (PPE) like helmets and gloves, contributing to a safer work environment. Their attention to detail ensures that processes, such as assembly line work in automotive production, are executed accurately, minimizing defects and rework rates, which can exceed 5% in some plants. Additionally, diligent workers often engage in continuous improvement practices, such as participating in Lean Six Sigma initiatives, aiming to reduce waste and enhance efficiency by up to 30%. Recognizing their contributions can lead to promising future opportunities, including promotions to supervisory roles or specialized training in advanced manufacturing techniques.

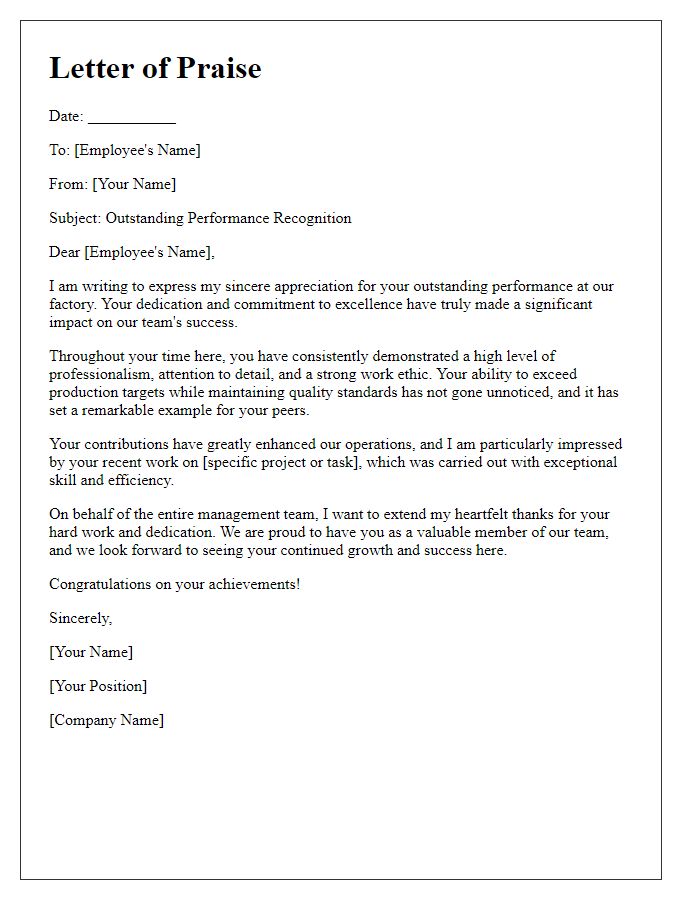

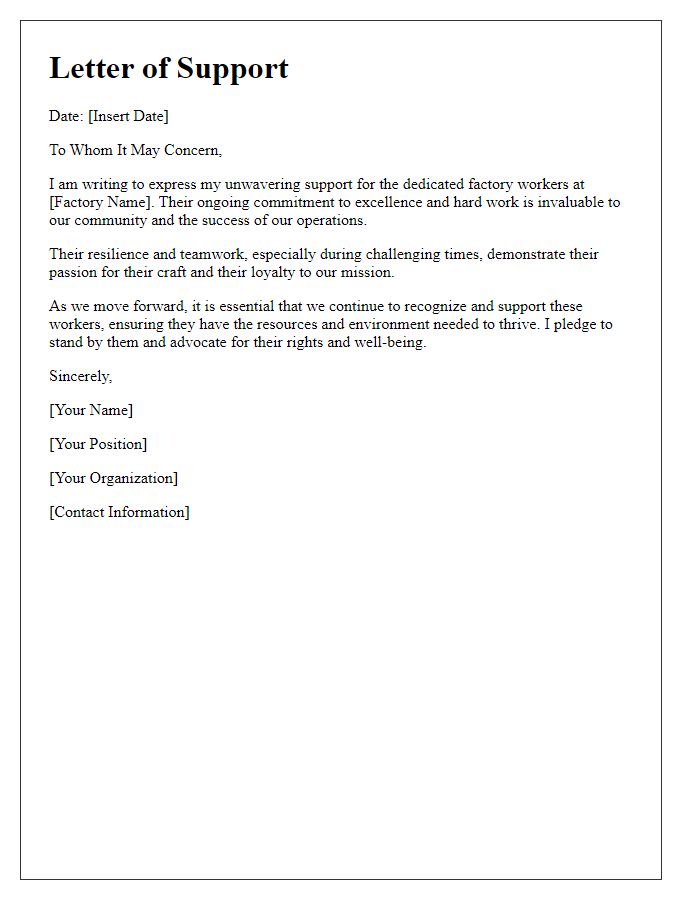

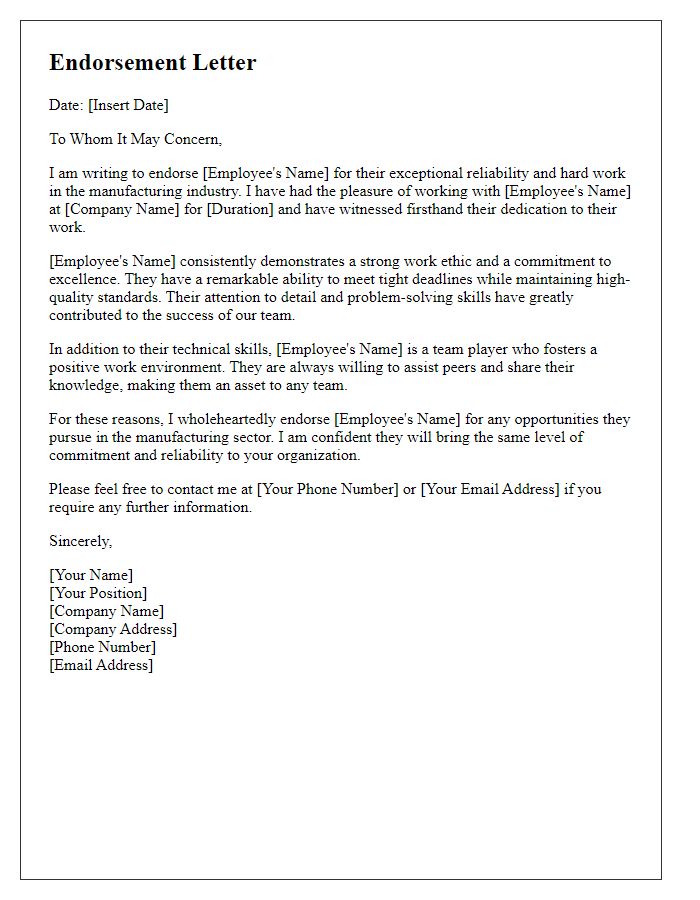

Letter Template For Factory Worker Diligence Samples

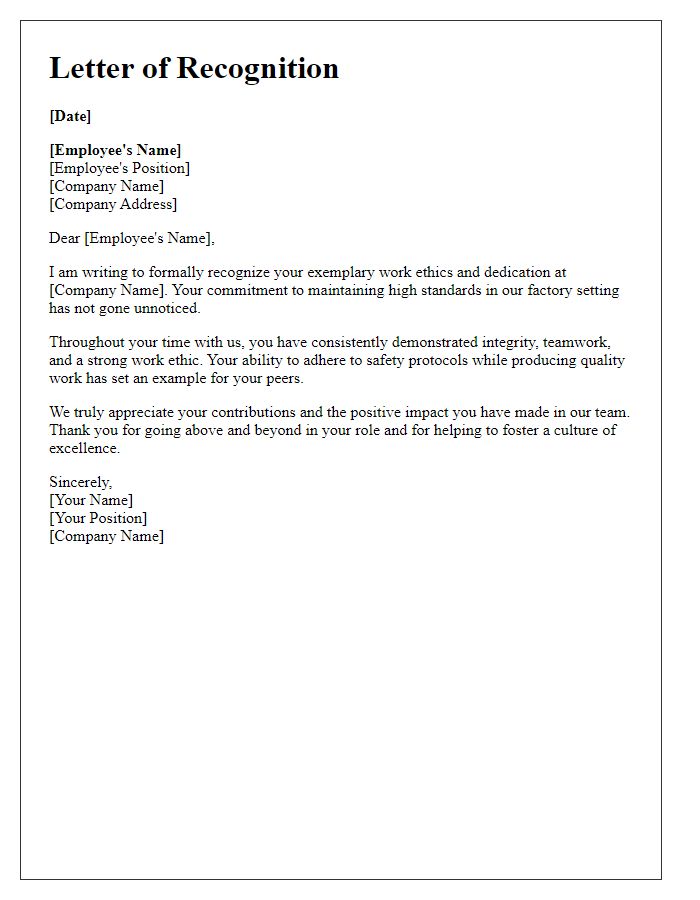

Letter template of recognition for exemplary work ethics in factory settings

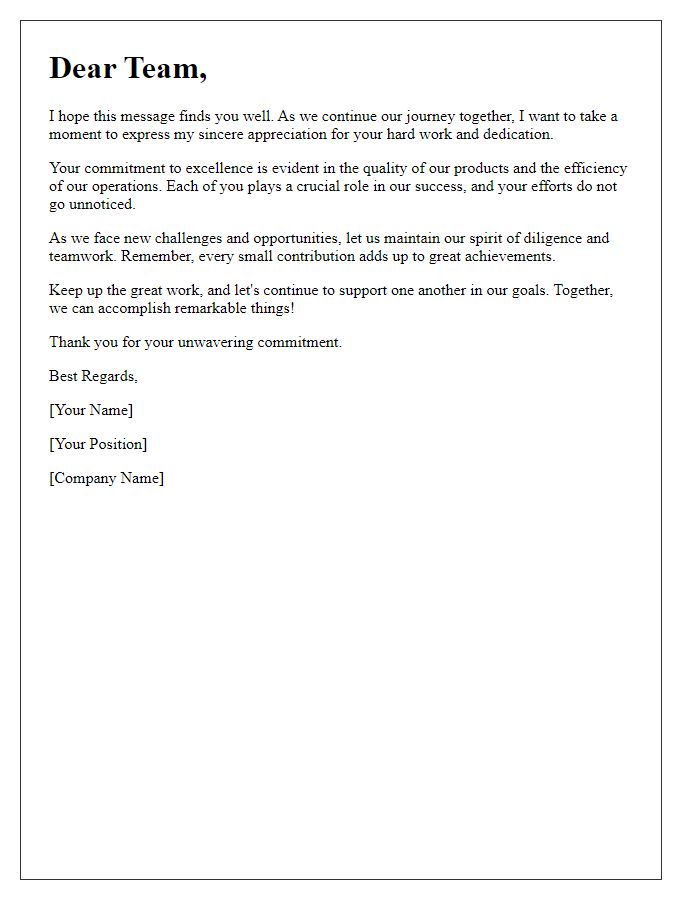

Letter template of encouragement for continued diligence among factory employees

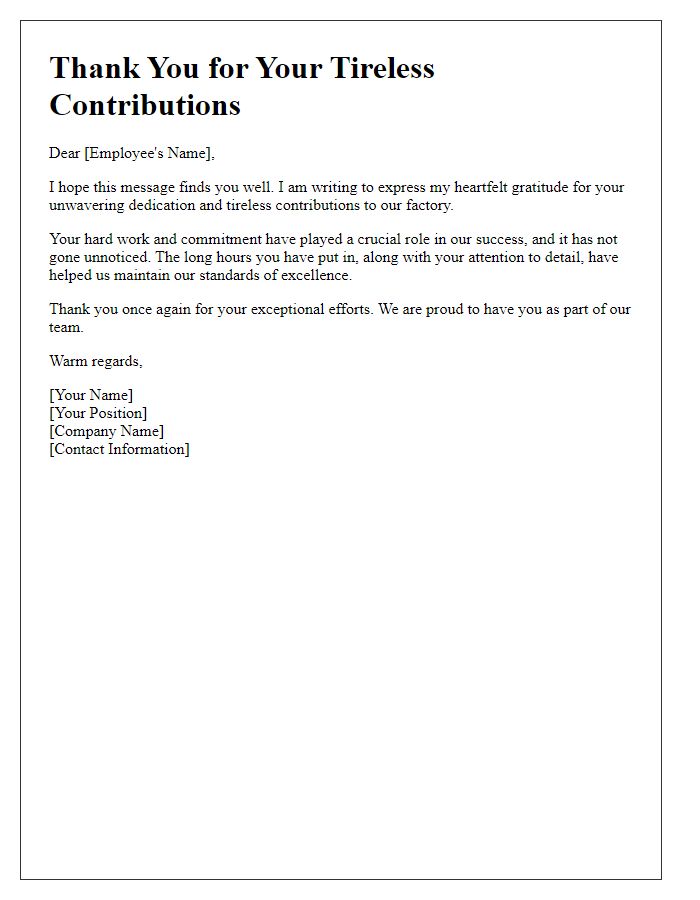

Letter template of thanks for tireless contributions in the factory environment

Comments