In today's fast-paced world, businesses must adapt and evolve to stay ahead of the competition. We're excited to share some important changes to our manufacturing operations that will not only enhance efficiency but also boost product quality. These updates are part of our commitment to innovation and excellence, ensuring we meet the ever-changing needs of our customers. Curious to learn more about these operational changes and how they can benefit you? Read on!

Audience Identification

Identifying the audience for announcing manufacturing operation changes is crucial for effective communication. Key stakeholders include manufacturing employees, such as assembly line workers and quality control personnel, who will be directly affected by changes in processes or workflows. Additionally, management teams, including production managers and plant supervisors, require insights into the operational shifts to ensure smooth transitions. Supply chain partners, including suppliers and distributors, must be informed to adjust logistics and inventory management accordingly. Finally, communication with customers is essential to manage expectations regarding production timelines and product availability, especially if changes impact delivery schedules. Tailoring the message to these diverse groups promotes clarity and minimizes disruption.

Purpose and Key Message

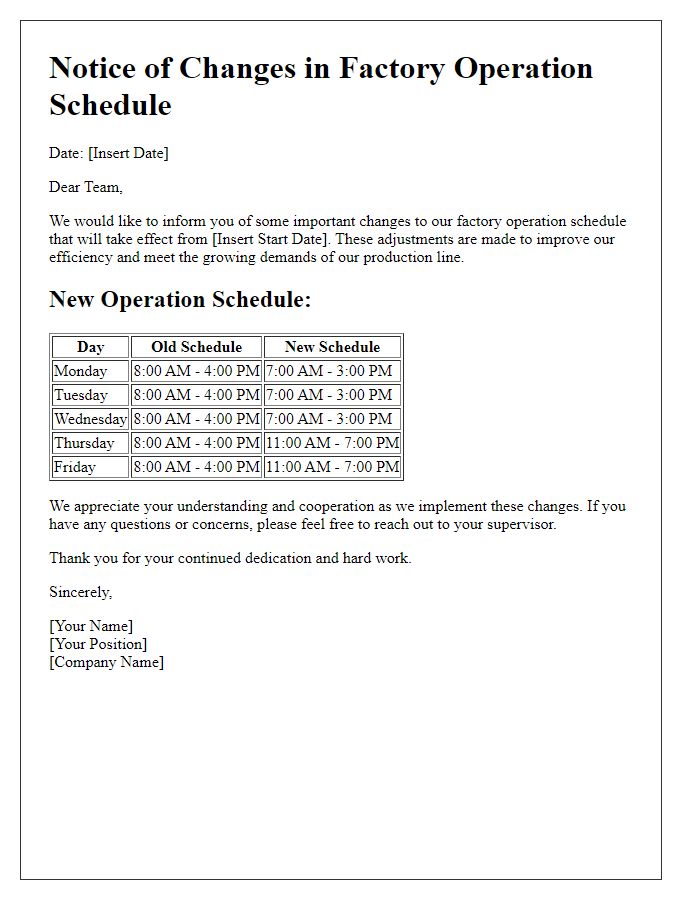

Manufacturing operation changes can significantly impact production efficiency and workforce management. The purpose of announcing these changes involves improving operational performance and meeting market demand. Key messages include the implementation of new technologies (such as automation systems), adjustments in workforce scheduling to enhance productivity, and streamlining supply chain logistics for better resource allocation. Additionally, communication regarding training programs (scheduled for Q1 2024) for existing employees ensures a smooth transition and fosters resilience during this operational shift.

Clear Explanation of Changes

The recent operational changes in the manufacturing facility, located in Detroit, Michigan, encompass a transition from traditional assembly methods to automated robotic systems to enhance productivity. This move is expected to increase production capacity by approximately 30% within the next six months. The implementation of advanced technologies like Internet of Things (IoT) devices will streamline monitoring and maintenance processes, reducing downtime significantly. Skill development programs for workers are also being introduced, aimed at equipping over 500 employees with knowledge in robotics and automation by the end of the fiscal year. These changes aim to position the company for competitive advantage in the evolving market landscape while ensuring consistent product quality and safety standards.

Impact on Stakeholders

Manufacturing operation changes can significantly impact stakeholders, including employees, suppliers, and customers. On October 5, 2023, the XYZ Manufacturing Plant in Springfield, Illinois will implement a shift from traditional assembly lines to advanced automation systems. This transition aims to improve efficiency by 30% and reduce production costs by 15%. Employees may experience changes in roles or training requirements for new technologies, while suppliers could face adjustments in order quantities and delivery schedules. Customers might see changes in product availability and lead times, necessitating proactive communication to manage expectations effectively. Overall, these operational changes are designed to enhance competitiveness in a rapidly evolving market landscape.

Contact Information for Queries

Manufacturing operations often undergo changes that can impact various stakeholders, including employees, suppliers, and customers. Notifications regarding such changes should clearly outline the reasons for the modifications, which can include economic factors, technological advancements, or shifts in market demand. Companies may provide a dedicated contact point for queries, ensuring open communication during transitions. This may include details such as a specific email address or a phone number, which allows affected parties to seek clarification, express concerns, or receive timely updates on the manufacturing procedures and policies. Such transparency fosters trust and facilitates smoother adjustments to the new operational framework.

Comments