Hey there! If you're wondering how to notify your clients about an aircraft maintenance delay, you're in the right place. Crafting a clear and concise letter can go a long way in maintaining trust and transparency. We'll guide you through the essential elements to include, ensuring your message is professional yet approachable. Ready to dive deeper into our letter template and tips? Let's get started!

Clear subject line

Aircraft maintenance delays can impact flight schedules significantly, leading to passenger inconvenience and operational challenges for airlines. Safety inspections, performed by certified aviation technicians, determine the airworthiness of aircraft modeled after specific regulations set by the Federal Aviation Administration (FAA). When unexpected issues arise, such as engine malfunctions or avionics discrepancies, thorough checks and repairs can cause a delay ranging from a few hours to several days. Effective communication strategies must be implemented to inform passengers regarding changes to their itineraries, keeping them updated on revised departure times or alternative arrangements that may involve rebooking flights or accommodations.

Detailed explanation of delay

Aircraft maintenance delays can arise from various factors, such as unexpected mechanical issues, parts unavailability, or labor shortages. For instance, if an aircraft requiring maintenance is discovered to have an engine problem, mechanics may need to conduct comprehensive inspections that extend beyond the scheduled timeframe. The procurement process for replacement components, particularly those sourced from specialized manufacturers, can contribute to further delays. Additionally, regulatory compliance checks mandated by aviation authorities, such as the Federal Aviation Administration (FAA), can add significant time to the maintenance schedule. This multifaceted scenario can result in the aircraft being grounded longer than anticipated, thereby impacting flight operations and passenger travel plans. Proper communication regarding these delays is crucial for managing expectations and ensuring safety standards are upheld.

Revised maintenance schedule

Aircraft maintenance delays can significantly affect flight schedules and passenger experiences. Revised maintenance schedules, typically due to unforeseen circumstances such as parts availability or technical issues, can extend the expected downtime of aircraft, leading to changes in departure times and potential cancellations. Airlines must communicate these adjustments promptly to ensure passengers are informed about their travel plans. An effective notification should include specific details such as the affected flight numbers, new maintenance completion dates, and alternative arrangements for passenger accommodation or rebooking options. Clarity and transparency are crucial in maintaining customer trust during these disruptions.

Contact information for further inquiries

Aircraft maintenance delays can significantly impact flight schedules and passenger experiences. Such delays often arise from necessary inspections, unforeseen technical issues, or regulatory compliance checks mandated by aviation authorities like the Federal Aviation Administration (FAA). For timely updates and further inquiries regarding flight status, passengers can reach out to customer service at the airline's designated contact numbers, typically found on official websites, or via email support. Additionally, social media platforms often allow for real-time communication with airline representatives, providing an alternative channel for assistance and information regarding alternate travel arrangements.

Reassurance of safety and compliance

Aircraft maintenance delays, especially for commercial airlines, can create significant operational challenges. During routine inspections and repairs, various components may require additional time due to unforeseen issues like parts availability or stringent regulatory compliance checks mandated by the Federal Aviation Administration (FAA). Compliance with safety standards is paramount, ensuring that all systems, including avionics, engines, and airframes, meet rigorous specifications. Each maintenance step adheres to a detailed checklist, often exceeding 100 items, to guarantee operational safety. While delays can inconvenience travel schedules, the priority remains unwavering: the safety of passengers and crew aboard, alongside the assurance that every aircraft will meet performance benchmarks before departure. These diligent practices reflect the commitment to maintaining airworthiness and operational reliability in the aviation industry.

Letter Template For Aircraft Maintenance Delay Notification Samples

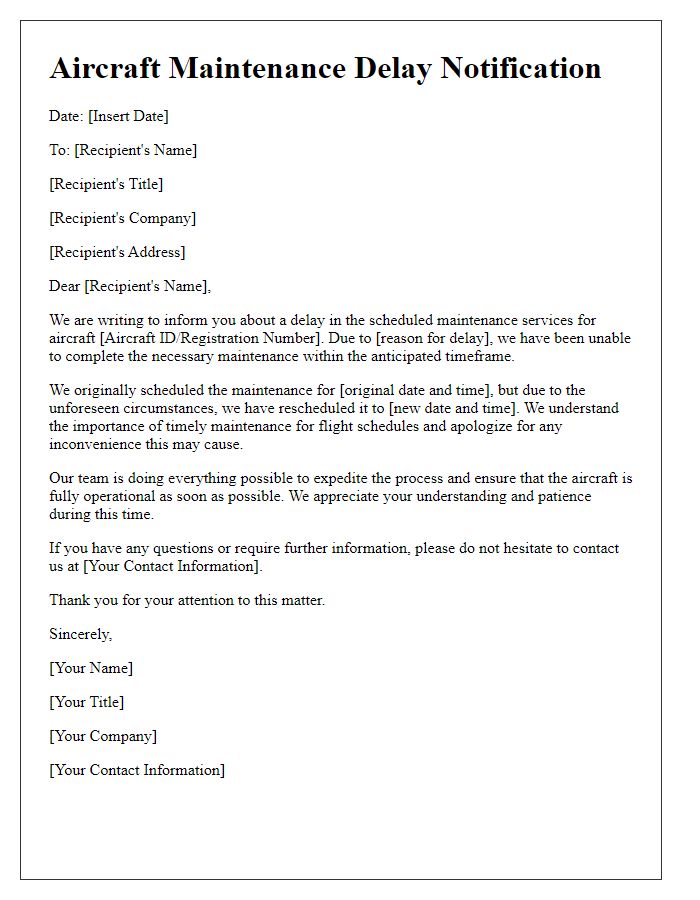

Letter template of Aircraft Maintenance Delay Notification for Scheduled Services

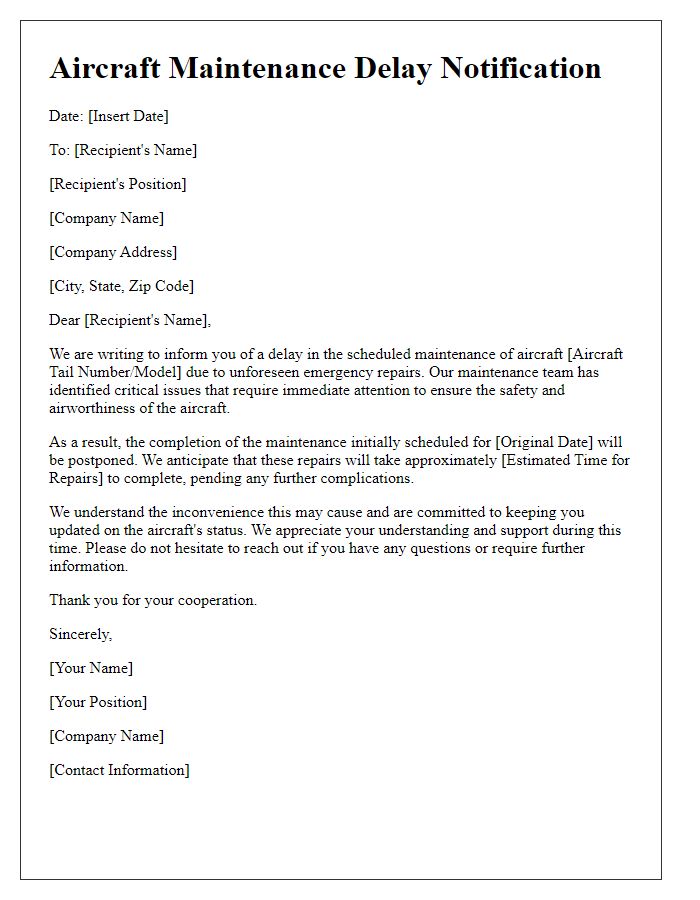

Letter template of Aircraft Maintenance Delay Notification for Emergency Repairs

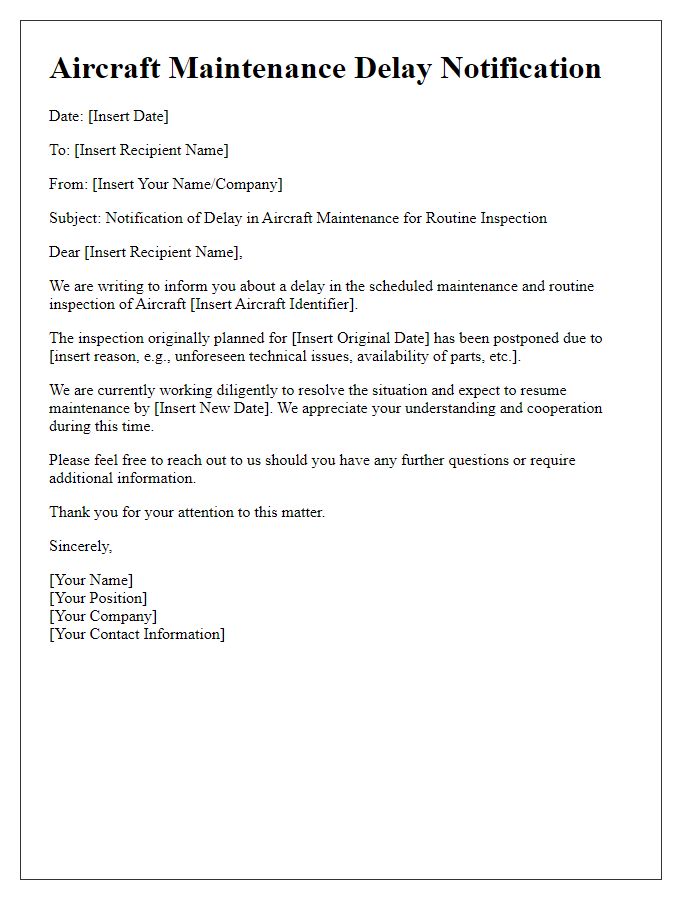

Letter template of Aircraft Maintenance Delay Notification for Routine Inspections

Letter template of Aircraft Maintenance Delay Notification for Unforeseen Issues

Letter template of Aircraft Maintenance Delay Notification for Regulatory Compliance

Letter template of Aircraft Maintenance Delay Notification for Parts Availability

Letter template of Aircraft Maintenance Delay Notification for Service Upgrades

Letter template of Aircraft Maintenance Delay Notification for Extended Downtime

Letter template of Aircraft Maintenance Delay Notification for Crew Scheduling Conflicts

Comments